Artex asbestos: how to test, NNLW vs non-licensed, safe drilling and removal steps

Jump To...

Supervisor inspecting an Artex ceiling wearing PPE

Quick answer

- You can’t tell by eye if Artex has asbestos. Get a sample tested by a competent person and a UKAS accredited lab.

- Most textured coatings are non-licensed work, but larger scale scraping or poor condition materials can be Notifiable Non-Licensed Work.

- Follow HSE Asbestos Essentials methods for small tasks like drilling or removing a small area using gel or steam. Use an H-class vacuum, keep it damp, wear an FFP3 mask and Type 5 or 6 disposable coveralls.

- If the coating is heavily degraded or you’re dealing with sprayed coatings or insulation, you’ll need a licensed contractor.

What Artex is and when it contains asbestos

Artex is a textured decorative coating used on ceilings and walls. In the UK, asbestos was phased out of textured coatings in the mid 1980s and fully banned in 1999. That means anything applied before 1999 could contain asbestos. The asbestos content in textured coatings is usually low by percentage, but the risk comes when fibres are released during disturbance. See HSE on common locations and materials containing asbestos for an overview of where you’ll find it in buildings built or refurbished before 2000 HSE locations and materials.

HSE rules in plain English: non-licensed vs NNLW vs licensed

- Non-licensed work: Many small textured coating tasks are classed as non-licensed work if exposure is sporadic and of low intensity. You still need the right controls, equipment and training. See HSE guidance on non-licensed work HSE non-licensed work.

- Notifiable Non-Licensed Work: Some textured coating jobs must be notified before starting, for example larger scale removal using gel or steam or if the coating is significantly degraded. The HSE is consulting on clarifying what counts as NNLW—the consultation runs until 9 January 2026, so watch for tighter definitions on the rules. See HSE on notifiable non-licensed work HSE NNLW and the HSE consultation.

- Licensed work: High risk materials like sprayed coatings and thermal insulation are licensed only. Textured coatings are normally not licensed work, but check the actual task and condition.

- Training: Anyone likely to disturb asbestos needs asbestos awareness as a minimum. Non-licensed work requires further task specific training and instruction. See HSE training overview HSE training.

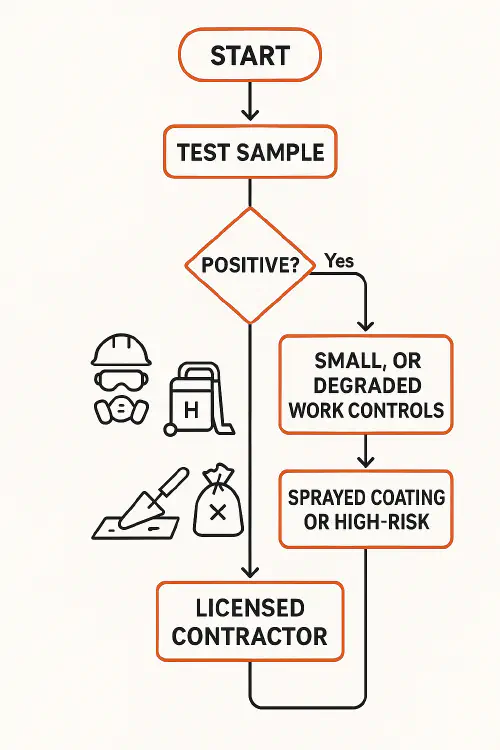

Decision flow you can use on site

Decision flow: test sample, then non-licensed or NNLW or licensed

- Start with a sample test. If positive and the task is small and controlled, it’s usually non-licensed. Use wet methods and H-class extraction.

- If it’s a bigger removal or the coating is in poor condition, it may be NNLW. Notify and keep records.

- If it’s sprayed coatings or insulation, stop and bring in a licensed contractor.

Testing options and getting a UKAS lab involved

- Prefer a UKAS accredited laboratory for analysis. A trained surveyor will take a small sample and send it for PLM analysis. Turnaround can often be next day depending on provider.

- If a client insists on a DIY kit, make sure they understand how to prevent fibre release and how to package the sample. Professional sampling is safer and recommended.

- Keep the sample area damp, isolate the space, and clean down with an H-class vacuum after taking the sample.

Safe method statements for common jobs

The methods below summarise HSE Asbestos Essentials task guidance for textured coatings. Always consult the full HSE guidance and adapt to your site RAMS.

Drill a single downlight hole in a textured ceiling

- Set up: isolate area, signage, no other trades. Switch off electrics in the area.

- Equipment: H-class vacuum with brush nozzle, FFP3 respirator, Type 5 or 6 disposable coveralls, gloves, spray bottle with water plus a little detergent, polythene sheeting, tape, waste bags for asbestos (red inner, clear outer where specified).

- Method:

- Lightly mist the surface. Place the H-class vacuum nozzle next to the drill point.

- Use a hole saw with the shroud connected to the H-class vacuum if available. Keep the area damp. Low speed, steady pressure.

- Immediately vacuum dust and debris. Wipe the area with damp rags. Double bag wipes and debris as asbestos waste.

- Clean down: H-class vacuum and damp wipe. Remove PPE carefully and dispose of single use items as asbestos waste.

Remove a small patch up to about 1 square metre using gel or steam

- Set up: isolate area and lay polythene sheeting. Prepare asbestos waste bags.

- PPE and equipment: as above plus a suitable gel remover or steam plate, long handled scraper, and a garden sprayer with water.

- Method:

- Score paint films if present. Apply gel remover, cover with plastic film to keep it wet. Allow dwell time per product instructions.

- Keep the coating damp as you lift with the scraper. Don’t sand. Work gently to avoid creating dust.

- Collect scrapings straight into a lined tray or onto your polythene. Double bag as asbestos waste.

- Clean down and record a statement of cleanliness when finished per HSE guidance.

Note: Larger areas or degraded coatings may trigger NNLW. Check the task against HSE criteria before you start.

For full context see HSE Asbestos Essentials overview and task sheets for textured coatings HSE Asbestos Essentials.

You may also find this short demonstration video useful for understanding the wet gel approach. Always follow HSE controls and only use for non-licensed tasks: How to remove Artex safely - YouTube.

When and how to notify NNLW

- Notify before work starts if the task meets NNLW criteria for textured coatings, for example larger areas removed by scraping or if the material is in poor condition.

- Keep a copy of the notification on file and on site. Keep records of workers involved and their training.

- See HSE’s NNLW guidance for criteria, what to include and retention of records HSE NNLW.

Waste, clearance and records

- Use asbestos waste bags or wrap in heavy gauge polythene. Double bag and label. Arrange disposal at a site that accepts asbestos waste.

- Use an H-class vacuum with HEPA filter for cleanup. Don’t use domestic vacuums.

- Complete a simple statement of cleanliness on completion and keep with your job file. See HSE Asbestos Essentials for examples HSE Asbestos Essentials.

- Keep training records, equipment maintenance records and NNLW notifications where relevant.

Quoting and pricing tips

- Build in time for sampling and lab turnaround. Many clients appreciate a fixed price for test and report with a clear plan based on results.

- Separate your price for containment and cleanup. Use a standard checklist to avoid missing PPE, waste and plant costs.

- For larger removals or where licensed work is needed, refer a trusted licensed contractor and add your project management fee rather than taking on work outside your scope.

Common mistakes to avoid

- Dry scraping or sanding textured coatings.

- Using a general vacuum instead of an H-class machine with HEPA filter.

- Skipping training. Awareness alone is not enough if you’re doing non-licensed work.

- Not checking whether a task tips into NNLW. Size and condition matter.

- Forgetting to document. Keep records of training, equipment checks, notifications and a brief statement of cleanliness after work.

What are people saying on Reddit?

Recent threads show real world concerns and sensible precautions from UK homeowners and trades. Useful reads:

- How bad really is asbestos in an artex ceiling r/DIYUK

- Artex found to have asbestos. Help needed r/DIYUK

- Downlights in artex ceiling. Options if it contains asbestos r/HousingUK

- Asbestos Artex - Skim r/DIYUK

Handy links

- HSE locations of asbestos and taking the right action HSE

- Asbestos Essentials overview and task shee…

Related TrainAR Academy articles:

- Near miss reporting on construction sites: simple steps, examples and a QR code setup

- Subcontractor onboarding checklist: right to work, CIS, induction and paperwork (UK construction)

- PAT testing for trades: legal requirements, how often to test, and a simple setup that prints certificates

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist