Construction performance reviews: templates, KPIs and how to run them on site

Jump To...

Quick answer

A performance review on a construction site is a short, structured conversation where a supervisor and a tradesperson look at recent work, agree what good looks like, set 1 to 3 clear goals, and sort any training or support. Keep it evidence based (diaries, QA checks, toolbox talk attendance), keep it regular (every 3 months with a 4 week check in), and keep paperwork simple.

Foreman and engineer in a site cabin reviewing a performance form with trade-specific KPIs

Why do reviews on site

- Fewer reworks and callbacks: reviews surface recurring quality issues and fix the cause.

- Better safety behaviours: use the review to reinforce PPE, permits, housekeeping and near miss reporting.

- Faster onboarding: new starters hit standard quicker with 30 day goals.

- Retention and morale: people stay when expectations are clear and progress is recognised.

- Client confidence: documented competence makes handovers and audits smoother.

Useful related guides:

- Keeping proof of toolbox briefings is easy with a QR sign in. See Toolbox talk attendance QR code.

- If you track cards and training dates, an internal passport helps. See CSCS digital skills passport: setup, site checks and a 30 day rollout plan.

What to measure: trade-friendly KPIs

Start with 6 to 8 headings most sites already record. Score on a simple 1 to 5 scale and add quick evidence notes.

- Safety and compliance: PPE use, permits to work, RAMS brief sign off, toolbox attendance, near miss reports raised.

- Quality: rework count, snag rates, photos match spec, test results first time pass.

- Productivity: output vs plan, task durations, first time fix, readiness of tools and materials.

- Housekeeping: waste control, return of plant, storage, working area tidy.

- Teamwork and communication: handovers, coordination with other trades, attitude with clients.

- Reliability: timekeeping, attendance, call out response.

- Skills growth: new tickets or training completed, ability to mentor others.

Examples by role

- Electrician: test sheet accuracy, containment quality, labels and schedules, EIC/EICR paperwork, isolation compliance.

- Plumber/heating: pressure tests, purge/flush evidence, leak rate, commissioning sheets, BUS/MCS evidence quality if relevant.

- Carpenter/joiner: finishes quality, tolerance checks, door set alignment, fire stopping records.

- Groundworker: levels, compaction tests, trench support, reinstatement quality.

- Plant operator: daily checks, fuel/oil logs, damage-free operation, banksman comms.

- Site supervisor: RAMS brief quality, daily diary completeness, coordination, short interval control, close out of actions.

Templates you can copy

Use one page. Keep it fast to complete at the end of a shift.

Suggested sections

- Details: name, trade/role, site, date, reviewer.

- Scores and evidence (1 to 5): Safety, Quality, Productivity, Housekeeping, Teamwork, Reliability, Skills growth.

- Wins since last review: 2 short bullets.

- Issues and fixes agreed: 2 to 3 bullets with owners.

- Goals until next review: 1 to 3 SMART objectives with dates and support.

- Training or tickets needed: e.g., abrasive wheels, work at height, test equipment.

- Sign off: both parties.

Free, trusted templates to adapt

- ACAS has free appraisal templates including simple formats suitable for manual workers.

- Considerate Constructors Scheme shares an appraisal template you can reshape to your company.

If you need sample wording for objectives and comments, see Example phrases.

Evidence and fairness (ACAS aligned)

Build reviews on facts and follow fair process.

- Monitor and record work reasonably and transparently (for example using daily diaries, QA checklists, telematics). See ACAS on monitoring performance.

- If someone is struggling, offer support first. If issues continue, switch to a formal capability route and follow the ACAS Code. See ACAS capability procedures and the Code of Practice.

- Make reasonable adjustments where health or disability affects performance and review them regularly. ACAS has a reasonable adjustments review template.

- Data protection: keep review records secure and for no longer than needed. Be clear how you use site data such as attendance, telematics and photos.

Run your first 30 day cycle

Week 0: Set the standard

- Agree the KPIs and 1 to 3 objectives per person. Explain the evidence you’ll use.

- Share the one page form and the date for the review.

Week 1 to 3: Collect light evidence

- Supervisors note quick examples in daily diaries and QA forms.

- Capture toolbox attendance with QR sign in. See Toolbox talk attendance QR code.

Week 4: Hold the review in the cabin

- 20 minutes max. Start with wins. Discuss scores and evidence. Agree fixes and simple goals.

- Book a 4 week check in for mid cycle and a 12 week full review.

Week 8: Check in

- Are goals on track? Any support or training needed? Adjust objectives if scope changed.

Week 12: Full review

- Update scores, new goals, and training plan. File the signed form.

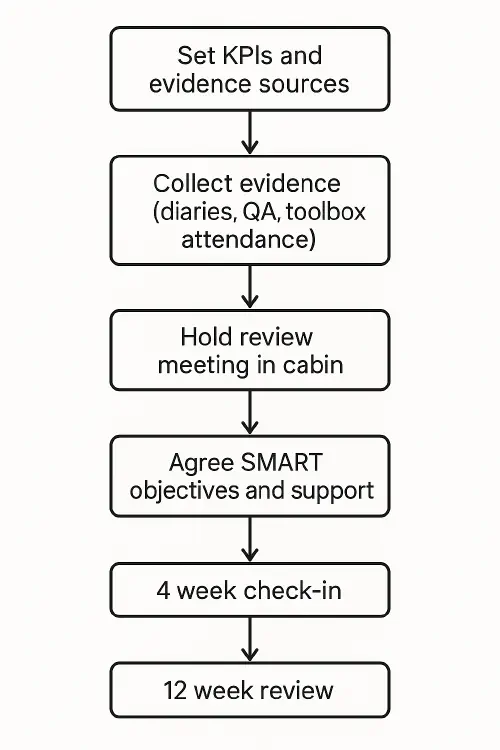

Flowchart: the review process

Simple flowchart of a site performance review process from KPIs to 12 week review

Common pitfalls and fixes

- Too many KPIs: cap it at 6 to 8. Depth over volume.

- Vague goals: write specific, dated actions with named support.

- No evidence: insist on photos, forms, or logs to back up scores.

- Annual only: do a quick 4 week check in between quarterly reviews.

- Mixing conduct and capability: use the right route. Persistent rule breaks may be conduct; difficulty meeting output after injury may be capability with adjustments.

- New starters drift: do a probation review at 4 weeks focused on safety and quality basics. For subcontractors, tie it to your Subcontractor onboarding checklist.

Example phrases that land with trades teams

Use plain English, point to evidence, and link to outcomes clients care about.

Positive

- Consistently meets RAMS and permits. Zero permit breaches this period.

- Quality is solid. No snags on last 10 door sets. Photos match spec.

- Strong teammate. Coordinated well with plumbing to avoid clashes on riser.

Constructive

- Improve housekeeping in the stair core. Aim for clear access by end of each shift. Supervisor to spot check twice a week.

- Test sheets need more detail. Add circuit references and signatures. Pair with senior for first two tests next week.

- PPE compliance dipped twice. Rebrief and keep glasses on during cutting tasks.

Goal examples

- Complete abrasive wheels training by 15 October and follow the cutting method statement on Block B. Supervisor to sign off.

- Reduce rework on containment by measuring twice and photo logging before fixings. Target zero rework next phase.

FAQs

How often should we do reviews on site?

Quarterly works well for most crews with a short 4 week check in. New starters benefit from a first review at 4 weeks.

What rating scale should we use?

Simple is best. 1 to 5 where 3 is on standard, 4 is above standard, 5 is role model. Always add a quick evidence note.

Can we include agency workers and subcontractors?

Yes. Keep it focused on safety, quality and coordination on your site. Keep a copy with your subcontractor records and link to induction paperwork and right to work checks.

What if performance does not improve?

Offer training or adjustments first. If issues persist, move to a formal capability process and follow the ACAS Code, allowing a companion in formal meetings.

Do we need a fancy app to do this?

No. A one page form plus your existing diaries, QA checklists and photos is enough. If you later adopt digital tools, keep the same headings and process.

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist