Digital handover pack with QR codes: set up O&M manuals and asset tags your client will actually use

Jump To...

Foreman scanning a QR code on plant while FM views a digital handover pack on a tablet

Quick answer

Put durable QR labels on rooms and assets that open the exact O&M page, drawings, warranties and maintenance tasks in your chosen platform. Keep it in a proper common data environment so the client’s team can scan, find, and update in seconds. This aligns with BS 8536 principles and the Building Safety Act’s golden thread for higher risk buildings.

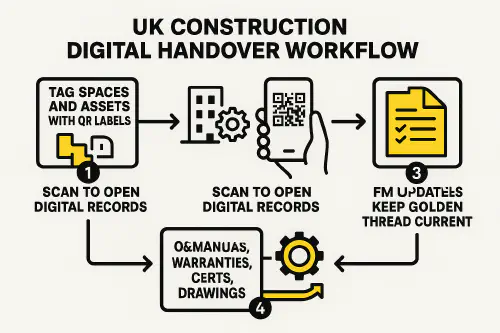

Flow: Tag spaces and assets with QR labels, scan to open records, view O&M, warranties, certs and drawings, FM updates keep golden thread current

Who this is for

- Main contractors, specialist subcontractors and installers who hand over plant or systems.

- SMEs and sole traders who want fewer call backs by giving clients a handover they actually use.

- Facilities and estates teams who want quicker fault finding and better evidence for audits.

Why this matters now in the UK

- Building Safety Act golden thread: higher risk buildings in England need digital, accurate, accessible information that’s maintained over time. See the government guidance on the golden thread.

- BS 8536:2022 pushes for defining information needs early and delivering usable operational information at handover. See the BS 8536 overview from the standards catalogue here.

- CDM 2015: the Health and Safety File is a legal duty and should be referenced inside your digital pack. See the legislation notes here.

How it works

- Space QR: at the door to a room or plantroom, a scan opens the room record with layout, local O&M extracts and safety info.

- Asset QR: on a maintainable asset, a scan opens its digital record with spec sheet, commissioning results, spares and the PPM checklist.

- Building Manual hub QR: a framed QR near reception or the FM office opens the digital index to O&Ms, drawings, certificates and fire information. Sensitive sections require login.

Step-by-step setup

- Agree the scope and IDs with the client

- Define what gets a QR: rooms, plantrooms, key assets.

- Pick simple IDs you can print on the label (e.g., AHU-02-L02). Map IDs to your asset register and handover documents.

- Choose a platform or CDE

- Use a system that supports QR-to-asset or QR-to-location and version control. For example, Dalux FM supports QR for drawings, locations and assets. See product docs on QR codes on drawings and Scanning QR for assets.

- Build the content once, link it everywhere

- For each room/asset add: brief description, manufacturer literature, commissioning, warranties, PPM tasks, as-built drawings or model views and photos. Use checklists from BSRIA BG 79/2020 as your baseline structure. Useful overview articles: help with Magazine and PBC Today.

- Generate your QR pages and test them

- Create role-based access. Keep public information separate from FM-only content.

- Test scans on iPhone and Android in poor light and with dusty labels.

- Print and place labels

- Use tamper-evident or anodised aluminium labels that survive chemicals, UV and pressure washing. Placement: visible but protected from abrasion. See UK suppliers in Label spec.

- Train and hand over

- Do a 30-minute walk-through with FM and contractors, scan labels on site, and record a short video. Add the video to the hub page.

- Aftercare

- Keep the documents live in the platform. Agree who updates what, how often, and where to log changes to maintain the golden thread.

Label spec that survives sites

Pick one of these depending on environment:

- Anodised aluminium (Metalphoto or equivalent): maximum chemical, UV and abrasion resistance for plant and external kit. Examples: Camcode Global’s Metalphoto plates (site) and Seton anodised aluminium tags (site).

- Under-surface printed polycarbonate: good chemical and scratch resistance for indoor locations. GSM Graphic Arts has UK options (example).

- Tamper-evident polyester (VOID): shows removal attempts. Good for portable tools and small assets. HellermannTyton has suitable stocks (example).

Spec tips

- Size: keep module size 0.6–0.8 mm or larger so phones scan quickly.

- Finish: matte or satin to reduce glare.

- Adhesive: 3M high-bond adhesives for painted steel and powder coat, or add mechanical fixings.

- Copy: print the human-readable Asset ID and a short help URL under the code.

UK suppliers (handy starting points)

- GSM Graphic Arts anodised aluminium QR labels (example product).

- MTM Products custom QR asset labels (site).

- Nameplates.co.uk aluminium and durable QR asset tags (catalogue).

- Dantech heavy-duty QR and Data Matrix plates (overview).

- Brady UK Defender Series materials for harsh environments (range).

Platform options and links

- Dalux FM: QR on drawings, rooms and assets with mobile scanning and permissions. Docs: QR on drawings, Assets, Locations.

- COBie export: if your client wants structured data for FM systems, plan to output an AIM in COBie. Primer: NBIMS COBie.

- UK BIM Framework resources on information management and CDEs: resource hub.

Related TrainAR Academy articles:

- Best asset tags and QR labels for tools and plant: what lasts on UK sites

- The 2026 Digital Handover Hack: QR Codes for Fast, Compliant O&M Packs (No CDE Required)

- O&M manual for construction: what to include, UK checklists and a fast handover process

Security, GDPR and access

- Keep sensitive data behind login and use role-based access for FM vs occupants.

- Only embed URLs in the QR; never embed data. Lock codes to your trusted domain.

- Add a safety note near public QR codes: if a code looks tampered with, don’t scan and go to your domain manually. See a recent BBC note on QR scams for context (article).

- Provide an offline fallback: a simple printed quick guide and a contact number; allow downloading critical O&M extracts for no-signal areas.

Costs and time to implement

- Labels: £0.25–£2.50 per label depending on size and material.

- Time: a small building with 60 rooms and 120 assets takes roughly 1–2 days to prepare content and 0.5 day to place labels and test.

- Platform: varies. Many CDE/FM tools bundle QR features.

Checklist before you print labels

- Confirm final asset and space IDs match the platform records.

- Test QR pages on site Wi-Fi and 4G in poor light.

- Check permissions on a non-admin phone.

- Freeze document versions and mark approved sets in the platform.

- Order 10 percent spare labels for replacements.

What are people saying on Reddit?

- Builders discuss what belongs in a handover pack and point to authoritative guidance. One commenter mentions using recognised guides as a baseline. Thread: Builders — What do you usually include in a handover pack?

FAQ

What should be in a digital handover pack?

At minimum: project overview, system O&Ms, manufacturer literature, commissioning results, warranties, PPM schedule, as-built drawings or model views, statutory certificates, fire and emergency information, training records and a pointer to the CDM Health and Safety File. BSRIA BG 79/2020 is a solid structure to follow.

Is an O&M manual legally required?

The O&M manual is typically a contractual requirement, not a legal one. The Health and Safety File under CDM 2015 is a legal duty and should be referenced and kept with the pack.

Do QR codes meet the golden thread requirement?

On their own, no. The golden thread is about accurate, secure and accessible information that’s maintained over time. QR labels are a simple way to get users into the right digital r…

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist