Digital M and E commissioning: simple checklists, forms and handover packs that pass first time

Jump To...

Engineer using a tablet to complete M and E commissioning checks in a UK plant room

Quick answer

Commissioning that passes first time is mostly about structure: a short pre-checklist, standard test sheets, and a neat digital handover. Use CIBSE Code A (air) with BSRIA guides (e.g., BG 49 for air systems, BG 29 for pre-commission cleaning of pipework), and follow Regulation 44 (commissioning notice) under the Building Regulations. Capture readings once, run auto checks, sign-off, and export a PDF pack for Building Control and the client.

Useful references:

- CIBSE Commissioning Code A: Air distribution systems (2024) cibse.org

- BSRIA BG 49/2024 Commissioning air systems (June 2024) bsria.com - covers ventilation design, functional testing, regulating systems and new technologies.

- BSRIA BG29/2021 Pre-Commission Cleaning of Pipework Systems bsria.com

- Building Regulations Regulation 44 Commissioning (legal duty to give notice) legislation.gov.uk

- F‑gas commissioning basics and leak checks (GB) gov.uk

What “good commissioning” means in the UK in 2025

Good commissioning is:

- Planned: design intent, method statements, instrument calibration up to date.

- Sequenced: set to work, prove flows, then balance and verify.

- Evidenced: readings, photos, and sign-offs packaged so Building Control can say yes without chasing you.

In practice you’ll align to:

- CIBSE Code A (air) for ventilation balancing and verification.

- BSRIA BG 49/2024 (air) and BG 29 (water) for step-by-step methods, forms and new technologies. BG49 was updated in June 2024 to reflect modern systems and testing approaches.

- Approved Documents L and F for energy and ventilation outcomes.

- Regulation 44: give a commissioning notice to Building Control for fixed building services.

- F‑gas rules for refrigeration and AC: qualified person, records, labels, and leak checks.

Simple workflow: air and water balancing without the drama

- Pre‑checks

- Drawings and design duty available on site.

- Plant safe to run, strainers clean, valves set to design preset.

- Instruments checked: hood, anemometer, manometer, thermometer, water flow meter.

- Set to work

- Vent: run fans, check rotation, measure supply and extract totals vs design. Fix obvious blockages/leaks.

- Water: flush complete and certified (BG29), fill/vent, pumps set, bypasses set, initial differential pressures recorded.

- Balance

- Air: use proportional method from the index terminal. Work from spine to branches to terminals. Record before/after.

- Water: start at index circuit. Use commissioning sets to achieve design flow, record delta‑P and lockshield positions.

- Verify and sign off

- Sample 10 to 20 percent for re‑measurement. Record non‑conformances and fixes.

- Capture photos of damper positions, valve tags, labels and panel setpoints.

- E‑sign the sheets with responsible person and date.

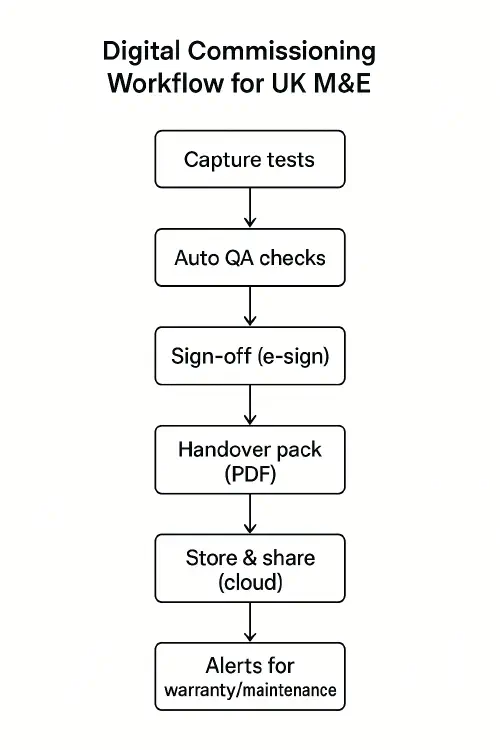

Mini flowchart

Digital commissioning workflow diagram

Digital evidence that Building Control accepts

For domestic and small commercial, Building Control usually accepts:

- Commissioning checklists from the installer or manufacturer (e.g., Benchmark), plus competent person scheme notifications where used.

- A Regulation 44 commissioning notice, evidenced by your completed test sheets and a summary.

- For MVHR/MEV, a Part F completion/commissioning sheet with measured airflows.

- For AC/refrigeration, F‑gas records, leak test results and compliant labels.

Links and official guidance:

- Approved Documents index gov.uk

- Approved Document F: ventilation gov.uk

- Regulation 44: commissioning notice legislation.gov.uk

- F‑gas guidance hub (qualifications, records, leak checks, labels) gov.uk

Templates you can copy

Use these headings in Google Sheets or your job app:

Air balancing sheet

- System/area, design duty, fan ref, date, engineer

- Terminal ref, location, design l/s, measured l/s (before), measured l/s (after), percent error, damper position, comments

Water balancing sheet

- System/loop, pump ref, setpoint, date, engineer

- Circuit ref, design flow l/s, measured l/s, delta‑P, valve position turns, lockshield set, comments

MVHR/MEV commissioning

- Room, design supply/extract, measured supply/extract, noise check, boost function, filter check, comments

F‑gas handover

- Unit ID, refrigerant type and kg, CO2e t, installer person and company certificate numbers, pressure test result, vacuum level held, initial charge added/removed, leak check due date, label applied

Handover summary

- What was tested, key results vs design, any snags, maintenance notes, warranty dates.

Automations that save serious time

- Auto checks in the sheet: conditional formatting to flag more than 10 percent off design, or missing readings.

- Photo to QR: stick a QR tag on valves and panels that links to the test sheet row or O and M note.

- E‑sign and share: export the whole pack to PDF and email to the client and Building Control in one go.

- Alerts: set reminders for F‑gas leak checks by CO2e band, filter changes, and warranty end.

- AI summaries: generate a client‑friendly summary of results and snags from your sheet.

What are people saying on Reddit?

Recent threads show common issues commissioning MVHR and balancing air systems, including resetting fan settings by mistake and confusion over bathroom extract with MVHR. Useful reading for pitfalls and client explanations:

- Accidentally reset fan commission reddit.com

- How do MVHR systems generally work with bathroom extraction? reddit.com

Related articles

- As-built drawings for small contractors: quick wins, what to include and simple digital workflows

- Heat pump commissioning checklist and live COP monitoring: simple UK workflow that saves callbacks

- Construction photo report from your phone: simple workflow, templates and tools

FAQs

Do I need a specific Part L “commissioning certificate” for heating?

Not a single national form. The legal duty is Regulation 44 to give Building Control a commissioning notice. In practice they accept the installer/manufacturer commissioning sheets plus your summary. See GOV.UK’s Approved Documents and Regulation 44 text.

Which standards should I quote for air balancing?

Quote CIBSE Commissioning Code A: Air distribution systems (2024) and BSRIA BG 49 Commissioning Air Systems. For ductwork leakage, reference BESA DW/143 and DW/144.

What counts as acceptable F‑gas commissioning evidence?

Use a qualified person and certified company, record refrigerant type and mass, pressure test and vacuum results, label the system, and set leak‑check intervals by CO2e. Keep records for 5 years.

How do I prove pipework is clean before water balancing?

Provide the BG29 pre‑commission cleaning certificate and sampling results. Without clean water, balancing will be unreliable and valves can foul.

Any quick wins to avoid re‑visits?

- Check filters and strainers before starting tests.

- Photograph damper and valve positions after final set.

- Put the PDF pack together on site while the readings are fresh.

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist