Heat pump commissioning checklist and live COP monitoring: simple UK workflow that saves callbacks

Jump To...

Engineer commissioning an air source heat pump at a UK semi

Quick answer

- Commissioning isn’t just turning it on. It’s verifying design assumptions, setting weather compensation, bleeding air, balancing flow and proving hot water cycles. Capture it once, properly.

- Add a low-cost monitoring kit during commissioning: one MID electricity meter, one MID heat meter and an OpenEnergyMonitor logger. You’ll see flow/return temps, kW and live COP. That makes faults obvious and cuts callbacks.

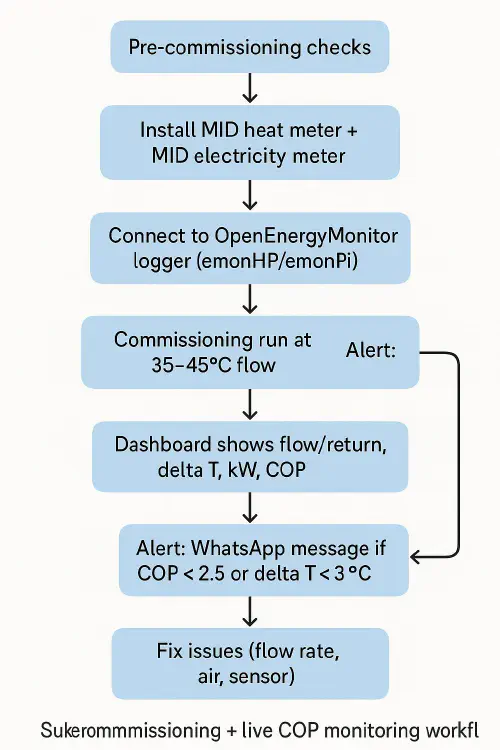

Flow of commissioning + COP monitoring with alerts

Who this is for

- Small UK firms installing or maintaining air-to-water heat pumps (1–20 engineers)

- Teams who want fewer return visits, clearer handovers and proof for customers, builders and warranty

What good commissioning looks like

Use the manufacturer checklist plus UK industry checklists as your baseline. The Heat Pump Association publishes commissioning checklists for air-to-water systems which mirror warranty requirements. See the HPA Air-to-Water Commissioning Checklists PDF. Air to Water Heat Pump Commissioning Checklist and Air-Water Commissioning Checklist v3.

Key points to hit on the day:

- System cleanliness: flush, inhibitor if required, strainers clean. No microbubbles in clear section when circulating.

- Fill pressure stable and correct. Expansion vessel pre-charge checked.

- Pumps and valves: correct direction, no cavitation noises, auto air vents purged.

- Electrical: polarity, earthing, RCD/RCBO trip checked, crankcase heater behaviour understood.

- Controls: weather-comp curve set for the property, room stats/zone valves synced with the heat pump logic.

- Hot water: cylinder target, anti-legionella cycle scheduled.

- Document flow rates, delta T and outdoor/indoor temps at multiple flow setpoints (e.g., 35 C and 45 C) and save to the job record.

Helpful overviews:

- Clade Engineering on what commissioning includes: inspection, setup, calibration and handover. Heat pump commissioning overview

- Baxi installer training page summarising commissioning requirements. Baxi heat pump commissioning

Set up live COP monitoring (cheap and accurate)

If you only measure electrical input, you can’t see performance. Add a heat meter as well.

- Electric input: fit a MID-approved electricity meter (e.g., SDM120 class) on the heat pump supply.

- Heat output: fit a MID-approved M-Bus heat meter (e.g., Sharky 775, Sontex Superstatic 440, Kamstrup 403 or Qalcosonic E3).

- Logger: connect both meters to an OpenEnergyMonitor logger (emonHP/emonPi/emonBase). Their UK guide explains Levels 1–3 and how Level 3 gives accurate COP. OEM heat pump monitoring guide

- Dashboard: publish to EmonCMS and optionally HeatpumpMonitor.org to benchmark against other UK installs. HeatpumpMonitor intro

Why this helps: With flow/return temps, kW and COP on a graph, air in the system, low flow, stuck TRVs or piping mistakes show up immediately. No guesswork.

Step-by-step workflow

- Pre-commissioning

- Verify design heat loss and emitters, clean system, check expansion vessel pre-charge, label zones.

- Fit MID electric meter and heat meter while pipework is open. Wire to logger.

- Cold checks

- Polarity/earth/RCD tests, insulation on external pipes, condensate route, clearances.

- First fire

- Set flow to 35 C, bleed and stabilise. Record: flow, return, delta T, flow rate, outdoor temp, electrical kW, heat kW, COP.

- Step to 45 C and repeat. Balance circuits if delta T is out of spec.

- improve controls

- Set weather compensation curve and disable unnecessary room stat interference. Schedule DHW and the weekly pasteurisation cycle.

- Alerts and evidence

- In your logger or automation, set an alert if COP < 2.5 at 35–40 C flow or delta T < 3 C for more than 15 minutes. Route to a WhatsApp team channel using Make/Zapier.

- Handover

- Export the commissioning graph and checklist PDF to the customer folder. Show the homeowner basic controls and where to find performance graphs.

Troubleshooting by the numbers

- Low delta T (< 3 C) at steady state: likely air, low flow, bypass stuck open, or undersized pump speed. Bleed, increase pump speed, balance, shut bypass.

- High delta T (> 10 C) with poor room temps: low flow or blocked strainers. Clean, balance, check valve positions.

- COP tanks during DHW only: cylinder coil undersized or target too hot. Try lower DHW temp and longer schedule; check coil kW rating.

- Defrost too frequent: check siting, clear airflow, and weather comp to avoid excessive flow temps in marginal weather.

For estimating COP without a heat meter, OpenEnergyMonitor’s basics page gives a sensible approach using Carnot-based estimates, but fit a heat meter for accuracy. OEM basics

Handover and evidence

- Use the HPA checklist and the manufacturer’s Benchmark/MID process. The UK Heat Pump Association checklists align with warranty expectations. HPA Air-to-Water checklist

- MCS process: register the installation on the MCS Installations Database shortly after commissioning, and ensure the Benchmark commissioning record is complete. MCS explains how MID and digital Benchmark tie together. MCS guidance on MID and Benchmark, Registering on the MID

What are people saying on Reddit?

- Octopus Energy customer heat pump diaries often comment that tuning flow temperature and weather comp post-commissioning makes the biggest difference. Octopus install experience

- UK homeowners share lessons learned in r/ukheatpumps threads about renovation timing and system balancing. Heat pump in renovation

Related articles

- Add WhatsApp to Google Business Profile: step‑by‑step for trades (plus Text and auto‑replies)

- Set up a Google reviews QR code for your vans and invoices: build the link, print it and automate follow ups

- WhatsApp booking bot for trades: setup, costs and Xero deposit links

FAQ

Do I need MCS to commission and handover?

You don’t need to be MCS certified to turn on a unit, but most UK domestic installations that will claim BUS grants or carry extended warranties expect commissioning to follow MIS 3005 and Benchmark, with records stored and the install registered on the MID by an MCS contractor. Check your contract and manufacturer terms.

What meters should I actually buy?

Any MID-approved electricity meter with Modbus (e.g., SDM120/SDM220) and a MID heat meter with M-Bus (e.g., Sontex 440, Kamstrup 403, Sharky 775). Connect to an OpenEnergyMonitor logger for dashboards and alerts. See OEM’s guide. OEM monitoring guide

Can I do this on radiators, not UFH?

Yes. You’ll typically target a slightly higher flow temperature. Balance TRVs open during commissioning so the pump sees consistent flow while you set the curve.

Can I estimate COP without a heat meter?

Roughly, yes, using temperature lift versus ambient, but it’s only a guide. For reliable troubleshooting and to defend your work, fit a heat meter. See OEM basics. COP basics

Any videos worth sharing with customers?

Heat Geek’s explainer on improving heat pump settings is accessible and UK-focused. How to improve heat pump settings

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist