Hot works permit template: UK checklist, fire watch times and how to use it on site

Jump To...

Hot works permit clipboard, extinguishers and a phone timer for fire watch on a UK refurbishment site

Who this is for

Small UK contractors, maintenance teams and site supervisors who need a simple, compliant way to control any task that creates heat or sparks: welding, cutting, brazing, soldering, grinding, heat guns and torch-on roofing. This guide focuses on UK HSE guidance and what UK insurers expect.

Quick answer

- If a job produces heat, flames or sparks and you can’t eliminate it, you should control it with a permit to work. HSE points to permit systems for hot work in construction and sets clear controls for before, during and after the work. See HSE Fire safety in construction and HSG250 on permit-to-work systems.

- UK insurers commonly require a documented hot work permit and recorded post-work fire watch. If you ever have a fire claim, missing permit paperwork can cause major headaches with your insurer.

Useful references:

- HSE Fire safety in construction (HSG168)

- HSE Guidance on permit-to-work systems (HSG250)

Free hot works permit template

Copy this into Word or Google Docs and print. Add your logo and project details. It follows HSE principles and aligns with typical UK insurer requirements.

HOT WORKS PERMIT (UK)

Project / Site: ___________________________ Location: ______________________________

Permit No: __________ Date: __________ Start time: ______ End time (validity): ______

Task description (specific): ______________________________________________________

Trade / Company: _______________________ Supervisor (on site): _____________________

Hot work method: Welding Cutting Brazing Soldering Grinding Heat gun Roofing torch Other: ______

Pre-work checks (issuer to confirm ✓)

[ ] RAMS reviewed and suitable for this task/location/date

[ ] Area cleared of combustibles (incl. below/above/adjacent voids)

[ ] Floors/penetrations/soft strips protected (non-combustible covers)

[ ] Fire detection isolated if needed (time window agreed) and re-enablement plan set

[ ] At least 2 suitable extinguishers in place and operatives briefed

[ ] Continuous fire watch nominated (name): __________________ Mobile: ______________

[ ] Nearby permits/works checked for conflicts (incl. roofing/timber frame)

[ ] Weather/wind/ventilation considered (if external)

Controls during work (operatives to confirm ✓)

[ ] Keep area under continuous fire watch during hot work and any breaks

[ ] Maintain good housekeeping and spark containment (screens/guards)

[ ] Stop if conditions change (wind, materials, detection isolation window expiring)

On completion (fire watch & sign-off)

Hot work stopped at: ________ Area cleared and cool to touch: ________

Continuous fire watch end (≥60 min): ________

Intermittent checks complete (usually to 120 min): ________ By: __________________

Final check made by thermal imaging (if available): Yes / No Time: ________

Fire detection re-enabled at: ________ By: __________________ (name/company)

Authorisations

Permit Issuer (competent person): __________________ Signature: __________ Time: ____

Hot Work Supervisor: __________________ Signature: __________ Time: ____

Fire Watcher: __________________ Signature: __________ Time: ____

Permit closed by: _________________ Signature: __________ Date/Time: ________

Notes: __________________________________________________________________________

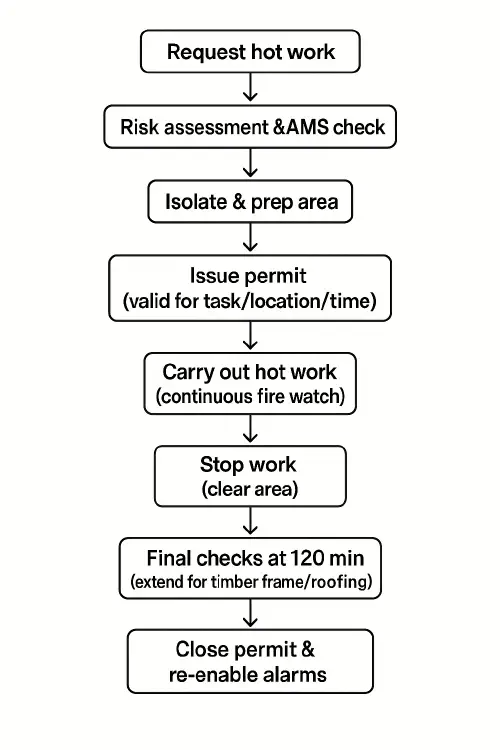

Hot works permit flow: request, RAMS check, isolate, issue, fire watch 60 minutes, final checks 120 minutes, close permit

What this template covers

- Specific task, location and time window (no blanket permits)

- RAMS and adjacent area checks (above, below, behind walls/voids)

- Isolation and re-enablement of alarms where needed

- Minimum two extinguishers to hand

- Named continuous fire watch during work and afterwards

- Recorded post-work checks and close-out

How to run it step by step

- Decide if you can avoid hot work. Can you use cold cuts or prefabrication off site? HSE advises eliminating hot work where possible.

- Write or review RAMS for the exact location and task. Add how you’ll protect adjacent voids and contain sparks.

- Prep the area. Remove combustibles, protect floors and voids, position at least two suitable extinguishers, and set up screens/guards.

- Coordinate alarms. If you must isolate detection, agree a time window and re-enable immediately after close-out.

- Issue the permit. Name the supervisor and the fire watcher. Set a clear validity period (often one shift). No permit, no hot work.

- Do the work under continuous fire watch. Stop if conditions change or controls lapse.

- Post-work fire watch. Record a continuous 60 minutes at minimum, with further checks to around 120 minutes, or longer for higher-risk substrates like timber frame or torch-on roofing.

- Close the permit. Re-enable alarms, record final checks and thermal imaging if used, sign off and file.

Fire watch times in the UK

Insurer expectations broadly align with HSE’s call to keep watching after the work stops. Typical UK positions:

- Standard hot work indoors: 60 minutes continuous fire watch after hot work stops, plus intermittent checks up to at least 120 minutes. Aviva’s procedure and Loss Prevention Standard set out this approach and advise extending where risk is higher.

- Timber frame / timber clad, or cavity-rich areas: extend significantly. Aviva notes a minimum combined watch of 4 hours in and around timber framed/clad structures.

- Torch-on roofing: Zurich advises longer checks (often 120 minutes) because hidden ignition is a known risk.

Links:

- Aviva Hot Work Permit Procedure and Hot Work Operations guidance

- Zurich Hot Works guidance and Smart Permit overview

- HSE Fire safety in construction (watch after-work, make checks 2 hours after and complete hot work at least 2 hours before end of day)

Evidence to keep for insurers

- Signed permit with named issuer, supervisor and fire watcher

- Times: hot work stopped, continuous watch end, final checks made and alarms re-enabled

- Photos of the setup (extinguishers, screens) and any thermal images

- RAMS copy, and any alarm isolation certificate or email from the fire alarm maintainer

- If roofing or timber frame: extra notes on extended watch duration and who checked when

Common mistakes and how to avoid them

- Blanket permits for a whole site or week. Always issue per task, location and time window.

- No checks in adjacent voids. Sparks travel; check above ceilings, behind linings, and below floors.

- Fire watch leaves early. Record names and times and schedule the final 120 minute check.

- Forgetting to re-enable detection. Put a calendar reminder and record who re-enabled and when.

- No extinguishers in reach. Keep at least two suitable units to hand and brief the team.

What are people saying on Reddit?

A recent thread from site supervisors highlights two practical points: notify building management early so alarms can be put in test, and if it’s your site, make sure your own hot work policy and permit are in place before any sparks start.

- Hot work permits? (ConstructionSupers): https://www.reddit.com/r/ConstructionSupers/comments/1lg7tsm/hot_work_permits/

Useful links

- HSE Fire safety in construction (HSG168): https://www.hse.gov.uk/pubns/books/hsg168.htm

- HSE Permit-to-work systems (HSG250): https://www.hse.gov.uk/pubns/books/hsg250.htm

- CITB hot work permit guidance note (GC07 PDF): https://www.citb.co.uk/media/21po0ydv/ge700-2020-gc07.pdf

- Aviva Hot Work Permit Procedure (PDF): https://static.aviva.io/content/dam/document-library/risk-solutions/hot_work_permit_procedure.pdf

- Aviva Hot Work Operations LPS (PDF): https://static.aviva.io/content/dam/document-library/risk-solutions/hot_work_operations_lps.pdf

- Zurich Hot Works guidance (PDF): https://www.zurich.co.uk/-/media/business/documents/our-expertise/smart_permit_hot_work_guide.pdf

- HSE Process fire risks topic page: https://www.hse.gov.uk/construction/safetytopics/processfire.htm

Related resources

- Construction site diary template: what to include, examples and a fast digital setup: https://academy.trainar.ai/construction-site-diary-template-what-to-include-examples-and-a-fast-digital-setup

- Training matrix template for construction: free Excel, CSCS and IPAF expiry reminders, and an automation you can copy: https://academy.trainar.ai/training-matrix-template-for-construction-free-excel-cscs-…

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist