Lead times and backorders in Tradify or Simpro: keep jobs on schedule

Jump To...

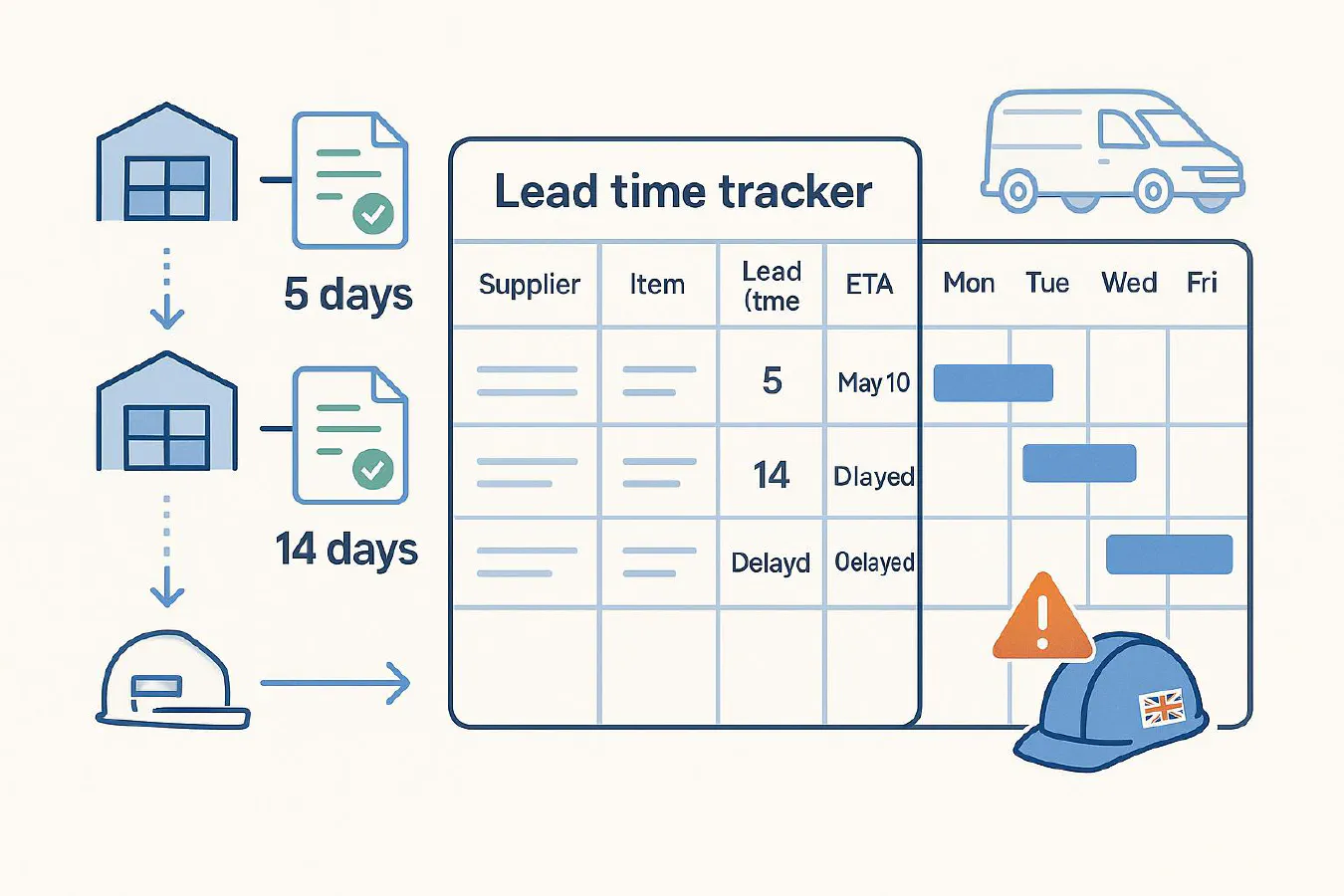

Flow: supplier lead times feeding a lead time tracker and a weekly calendar with job clash warning

Quick answer

- Simpro handles backorders natively: part-receive what arrived, the rest stays outstanding and is visible on the Supplier Back Orders report.

- Tradify doesn’t have a dedicated backorder status: use partial bills to keep the PO open or duplicate the PO to split backordered lines.

- Put supplier lead times in your item/supplier records (Simpro) or the PO Delivery Date (Tradify). Then mirror ETAs into a simple Google Sheet and push them to your Outlook calendar with Power Automate, so planners can see clashes before they happen.

Who this is for

- Owner-operators, office managers and dispatchers using Simpro or Tradify who keep seeing engineers turn up before parts land.

- Teams who schedule in Outlook/Teams but buy through Tradify/Simpro.

Workflow at a glance

- Capture lead times where you buy: item/supplier in Simpro; Delivery Date on POs in Tradify.

- Receive deliveries properly: part-receive goods that arrive; leave the rest outstanding.

- Track the outstanding list daily by supplier and ETA, chase late items.

- Mirror ETAs into a calendar so schedulers see realistic start dates.

- Review two KPIs weekly: average lead time by supplier, overdue backorders.

Simpro: set lead times, part-receive, track backorders

Where to track backorders: Reports > Suppliers > Back Orders. Filter by supplier, PO, due date. See what’s outstanding at a glance. Reference: Supplier Back Orders Report | Simpro

Create the PO correctly: use a Catalogue PO (not Description-only) so you can part-receive later. Reference: How to Create a Purchase Order | Simpro

Part-receive a delivery (leaves backorder outstanding): Purchase Order > Options > Create a Receipt > enter only quantities you actually received; finish receipt. The rest stays outstanding for the next delivery. Reference: How to Receipt a Purchase Order | Simpro

Invoices don’t “fill” backorders: importing a supplier invoice won’t increase quantities still on backorder. Reference: Import Supplier Invoices | Simpro

Keep lead times current: use Automatic Catalogue Syncing for UK suppliers where available (e.g., Rexel) to keep item data fresh. Reference: Automatic Catalogue Syncing (UK) | Simpro

Practical tip: add ETA notes per backordered line on the PO so dispatch can see the promised date without opening the receipt trail.

Tradify: delivery dates, partial bills and a simple backorder tracker

Delivery Date field: set the supplier’s promised date on the PO header. Tradify doesn’t auto-calc from lead time; enter it manually when the supplier confirms. Reference: Create Purchase Orders on Tradify (Web)

Handle partial deliveries: convert the PO to a Bill for items that arrived now and leave “Mark purchase order as billed” unticked so the PO stays open until the rest turns up. Reference: Convert a Purchase Order to a Bill

Splitting true backorders: duplicate the original PO and move outstanding lines to the new PO with an updated Delivery Date. This keeps ETAs clean and suppliers accountable.

Make lead times visible: use the PO Reference/Description to record “Supplier quoted 10 working days” so planners don’t over-promise. Reference: Add extra detail with Reference/Description

Turn ETAs into calendar blocks and warnings (Google Sheets + Power Automate)

Why: engineers get booked before parts arrive because ETAs live inside POs where the dispatcher never looks. Fix it by mirroring ETAs into a shared “Lead time tracker” sheet and auto-creating calendar events.

What you need

- A Google Sheet with columns: Supplier, Item, PO No, Qty, ETA, Site/Job, Status.

- Power Automate to create an Outlook calendar event when a new ETA is added or changes.

Steps

- Sheet: add one row per line on a PO that’s backordered or has an ETA beyond tomorrow.

- Power Automate flow: trigger on “When a row is added or modified” (Google Sheets). If EventId is empty, create an event; if not empty, update it.

- Create event field mapping:

- Title: “PO 12345 – Valve x4 – ETA from Rexel”

- Start: ETA date/time; End: ETA + 30 min

- Location: Supplier or Delivery point

- Body: link to the PO, notes from supplier

- Attendees: dispatcher + buyer

- Write the Outlook EventId back to the sheet so edits update the same event.

Useful expressions (Compose steps)

concat(items('Apply_to_each')?['StartDate'], ' ', items('Apply_to_each')?['StartTime'])

Video walkthrough (similar flow, Excel instead of Sheets):

If you prefer Zapier, set trigger = New/Updated Row in Google Sheets, then Create Detailed Event in Google Calendar using the ETA column. For Outlook, Power Automate is the most reliable route.

Daily dispatcher routine that actually works

- 08:00: Open “Lead time tracker.” Filter Status = Overdue or due today. Chase suppliers on anything due today not on the van.

- 08:30: Move jobs that depend on overdue items. Notify customers via your normal channel. Handy: Dispatcher playbook for trades

- 09:00: Review new POs raised yesterday; add any ETAs over 2 days into the tracker.

- 15:00: Second check for deliveries; update ETAs and statuses before the team sets tomorrow’s plan.

KPIs and alerts to stop surprises

- Average lead time by supplier (last 30/90 days). Swap to faster suppliers if possible.

- Late delivery count by supplier per month.

- Backorders open over 14 days.

- Calendar warnings: if a job start is inside the ETA window, flag it red.

UK specifics: VAT on POs, bank holidays and supplier comms

- VAT on purchase orders: ensure purchase tax codes are correct on suppliers and items; partial receipts/backorders don’t change VAT treatment, just when costs hit. Check with your accountant if you accrue on receipt.

- Bank holidays: suppliers usually quote working days. During peak holiday periods, pad the ETA by 1–2 days or ask for a firm date.

- Comms: when chasing, reference their delivery promise and your PO number. If lateness risks a day rate on site, say so; suppliers tend to escalate when site costs are at stake.

Template: light-weight lead time tracker

| Supplier | Item | PO No | Qty | Lead time (days) | ETA | Site/Job | Status |

|---|---|---|---|---|---|---|---|

| Rexel | 22mm isolation valve | PO-12345 | 4 | 5 | 2025-10-07 10:00 | 14 Acacia Ave | Due |

| City Plumbing | Heat pump filter | PO-12360 | 1 | 14 | 2025-10-18 09:00 | The Oaks | Backorder |

Status values suggested: Due, Overdue, Partial, Backorder, Received.

Pitfalls and quick fixes

- Booking before a firm ETA: don’t. Book provisionally and add a calendar warning tied to the ETA event.

- Not part-receipting (Simpro): you’ll lose visibility. Always receipt what actually arrives.

- Leaving PO marked billed (Tradify) after the first drop: the PO disappears from your radar. Only mark billed when fully complete.

- Mixing Description-only POs with Catalogue items (Simpro): you can’t part-receive Description-only orders—use Catalogue POs for tracked items.

Related reading

- Turn supplier delivery notes and photo PODs into van stock updates automatically (Tradify or Simpro)

- [Automate supplier quotes and POs with Xero: compare prices, approve fast and avoid overpaying](https://academy.trainar.ai/automate-supplier-quotes-and-pos-w…

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist