LOLER and PUWER on site: simple plant inspection setup with QR codes, WhatsApp and a printable checklist

Jump To...

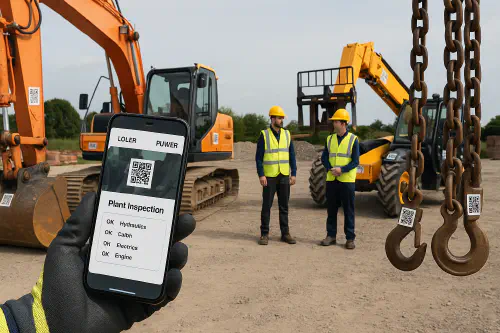

Engineer scanning a QR label on a telehandler to open a LOLER/PUWER checklist

Quick answer

- LOLER applies to lifting operations and equipment. Typical intervals: 6 months for lifting people and for lifting accessories like slings and chains, 12 months for most other lifting equipment, unless your competent person sets a different period based on risk. See HSE guidance on thorough examinations of lifting equipment.

- PUWER applies to all work equipment. You must keep equipment suitable, maintained and inspected at suitable intervals. See HSE’s PUWER overview and Inspection of work equipment.

- A low-friction setup for small teams: QR label on each item opens a short mobile form. You capture checks, photos, defects and a signature, auto-file to a logbook, and WhatsApp a copy to a site group for time‑stamped evidence.

LOLER vs PUWER in plain English

- LOLER = specific to lifting kit and lifting operations. Focus on planning lifts and doing periodic “thorough examinations” by a competent person.

- PUWER = all work equipment. Focus on daily/weekly checks, maintenance and safe controls/guarding/training.

- On a site with a telehandler:

- PUWER covers its general safety, guards, controls, training and routine checks.

- LOLER covers the lifting parts and thorough exam frequency. Accessories like chains and slings are typically 6‑monthly.

Helpful references:

- HSE LOLER hub: hse.gov.uk/work-equipment-machinery/loler.htm

- HSE thorough examinations page: hse.gov.uk/work-equipment-machinery/thorough-examinations-lifting-equipment.htm

- HSE PUWER overview: hse.gov.uk/work-equipment-machinery/puwer-overview.htm

What HSE expects in practice

- Suitable equipment for the task and environment.

- Planned inspections at suitable intervals by a competent person, with records kept.

- For LOLER items, a written report of thorough examination, defects reported promptly, and next due date recorded.

- Operators briefed and trained; controls clearly marked; defective kit taken out of service.

If you need a refresher on RAMS and briefings, see our guide: RAMS for UK construction.

Set up a QR-led inspection flow

What you need

- A label printer and durable QR labels (Brady/Zebra are common)

- A simple form tool (Google Forms, Microsoft Forms, SafetyCulture, Typeform)

- A cloud folder structure for logbooks (Google Drive, OneDrive)

- Optional: a low‑code tool for automations (Zapier, Make), or your service software if it supports assets

Steps

- Create one mobile form per class of kit

- Telehandler daily check (PUWER)

- Lifting accessories 6‑monthly exam capture (LOLER accessories)

- Chain/sling ID, SWL, condition, certification dates

- Generate a share link that opens the right form

- Print a QR label for each asset and stick near the operator position or on the accessory tag

- Scanning opens the form prefilled with asset ID via URL parameter

- On submit, auto‑save to Drive/OneDrive in a folder path like Plant/Telehandler/Asset‑123/2025‑09‑21‑daily‑check.pdf

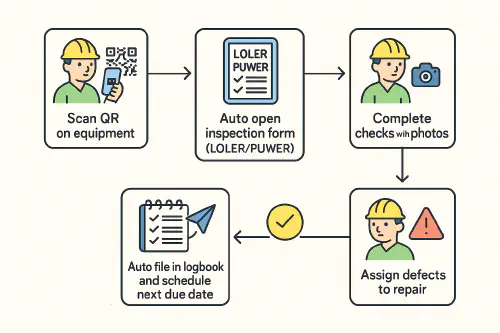

Flowchart: scan QR, complete LOLER/PUWER checks, auto file, schedule next due, assign defects

Tips

- Use clear photo prompts: hook, chains, forks, brakes, steering, alarms, load chart, CE/UKCA plate

- Force a signature and name for accountability

- Add a checkbox: “Defect found – take out of service” to kick off a repair

Create a simple WhatsApp evidence trail

Why: supervisors and clients respond to WhatsApp. It’s fast, dates are visible, and you can broadcast to the team.

- Create a site WhatsApp group named “Site‑ABC Safety Evidence”

- When a form is submitted, post a summary with two photos and a Drive link

- You can do this with Zapier/Make via WhatsApp Business API providers like 360dialog or Twilio. If you don’t have API access, share manually from the phone right after submission.

- Keep personal data minimal; store the full report in your Drive. See HSE guidance and basic GDPR practice for retention.

Related reads in the Academy

Printable plant inspection checklist (free)

For a paper backup or if phones are banned in certain areas, print a one‑pager and keep it in the cab.

- PUWER checklist examples: HSE inspection of work equipment and a simple downloadable example from High Speed Training: PUWER checklist PDF

- LOLER focus points: condition of lifting parts, hooks, chains, slings, safety latches, SWL marking, alarms; see HSE’s thorough examination guidance

Print tip: add your asset ID at the top and the next due date so drivers see it every day.

Automations: reminders, defect tickets and logbooks

- Reminders

- Use calendar reminders for next LOLER due dates: 6 or 12 months as applicable. Add a week‑before nudge.

- For PUWER daily/weekly checks, set a WhatsApp Broadcast each morning with a form link.

- Defect tickets

- Auto create a task in Trello/Asana or a job in your service software when “Defect found” is ticked. Attach photos and assign to the plant fitter.

- Logbooks

- Keep a per‑asset folder with subfolders for “Daily/Weekly checks,” “Thorough exams,” “Repairs,” and “Certificates.” This makes HSE or client audits quick.

Common mistakes to avoid

- Mixing up servicing with a thorough examination. A service is not a LOLER exam.

- No competent person defined. Name who does thorough exams and keep their reports.

- Missing the accessories. Chains, slings, shackles usually need 6‑monthly exams.

- No audit trail. If it’s not recorded and findable, it did not happen in the eyes of a client or HSE.

- Over‑long forms. Keep the daily check to 90 seconds so it actually gets done.

FAQ

Is LOLER every 6 or 12 months?

HSE’s typical periods are 6 months for lifting people and for lifting accessories, and 12 months for other lifting equipment, unless a competent person sets different periods based on risk. See HSE pages linked above.

Do I need both LOLER and PUWER checks on the same machine?

Yes. PUWER covers general safety and routine checks. LOLER applies to the lifting function and thorough examinations.

Can WhatsApp be used for compliance evidence?

Yes if you keep the actual records in your document system and only share summaries in WhatsApp. Avoid posting personal data. Back up photos and reports to Drive/OneDrive.

Who counts as a competent person for a thorough examination?

HSE says a competent person needs practical and theoretical knowledge and experience to detect defects and assess their importance. Many firms use independent inspection bodies for impartiality.

Any good explainer video on thorough examinations?

A clear overview is “Understanding LOLER #3 – Thorough Examination” by InspHigher on YouTube.

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist