Predictive van stock: how to lift first-time fix and cut repeat visits

Jump To...

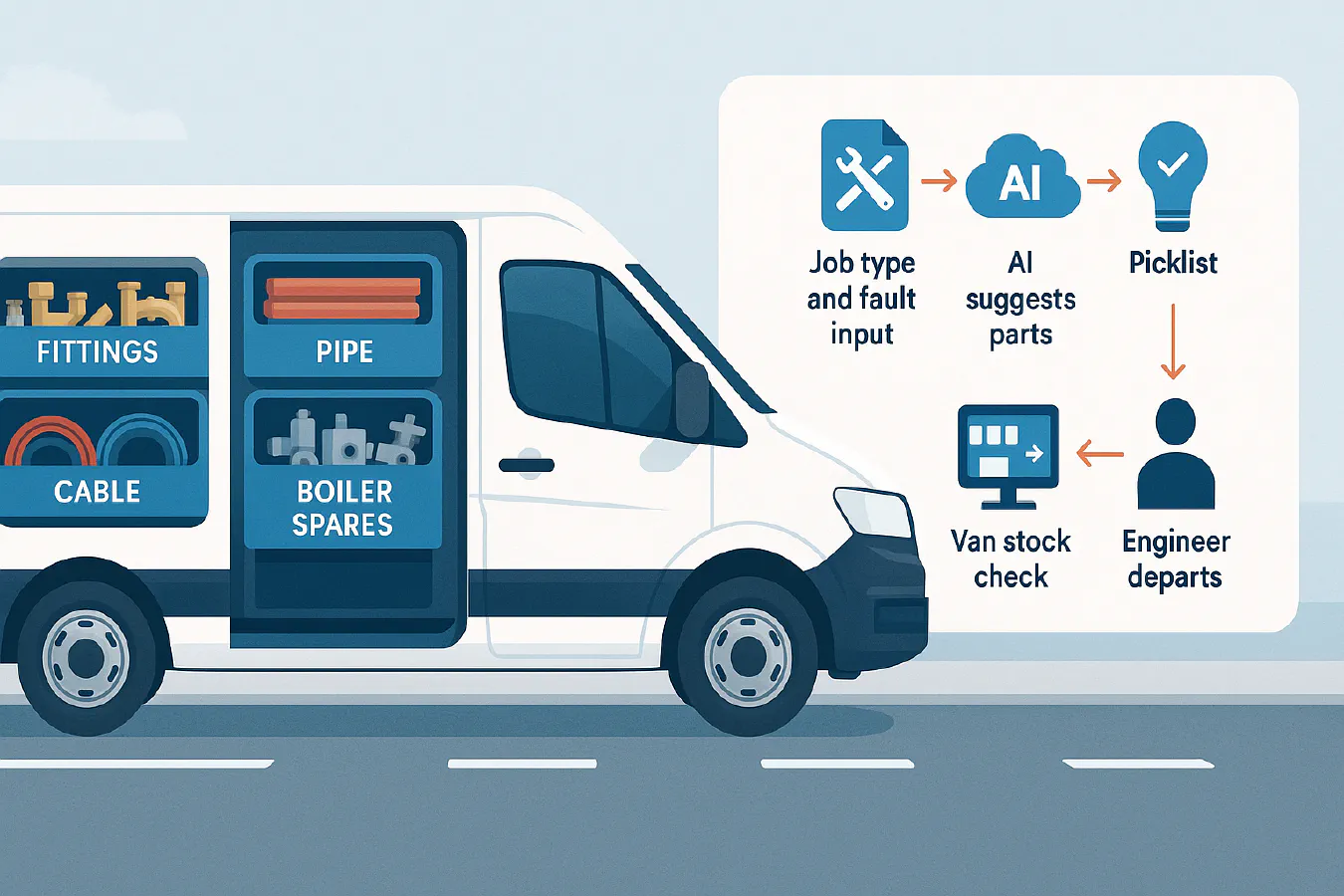

Organised trade van with an overlay showing a predictive parts flow from job to picklist to van stock and merchant click and collect

Who this is for

- Owner-operators and ops managers in plumbing, electrical, heating and multi-trade firms who want to increase first-time fix and reduce return visits.

- Teams already using a job management app (ServiceM8, Jobber, Tradify, Simpro, Commusoft) and wanting smarter van stock without turning into a warehouse.

Quick answer

Use your job history to predict the likely parts for each upcoming job, turn that into a picklist, then check against van stock. Anything missing is ordered for Click and Collect before the engineer sets off. Field-service benchmarks suggest top performers achieve ~85 to 90 percent first-time fix, while mid-pack sits around the mid 70s. Well implemented parts prediction and pre-staging can meaningfully move your figure in a quarter. See background on definitions and context at Totalmobile and wider benchmarks via Field Technologies Online and Aquant’s 2025 report summary (GlobeNewswire).

How it works

Think of it as a small loop that runs every afternoon for tomorrow’s jobs:

Job type + fault description + photos

↓

AI suggests likely parts and quantities

↓

Picklist generated per job

↓

Compare with van stock list (live)

↓

Order missing parts for Click & Collect

↓

Engineer departs with a complete kit

This doesn’t require “big AI projects.” Simple models and rules, plus tidy historical data, are enough to get started. Many teams begin with rules-by-template, then add AI suggestions as data grows.

What you need

- Job data: Recent jobs grouped by job type with outcomes and which parts were used. Even a three to six month slice is useful.

- A van stock baseline: A light list of staples you always carry (consumables and your top 20 fittings).

- Somewhere to hold picklists: Your job app notes or a shared Sheet is fine to start.

- Merchant Click and Collect nearby. For example, Screwfix’s Click and Collect can be ready in as little as 1 minute when an item is in local stock, with next-day for items shipped to store (see official Screwfix FAQ).

For racking and labels, see our guide on van stock control with barcodes.

Step-by-step playbook

1) Map your most common jobs and parts

- Export the last 3 to 6 months of jobs. Group by job type (e.g., boiler no heat, leaking trap, RCD tripping, new shower install).

- For each type, list the parts that were actually used. Start with the top 10 to 20 items per job type.

- Output: a simple lookup table: job type → usual parts and typical quantities.

2) Create starter picklists (rules first, AI later)

- Use your lookup table to auto-fill a picklist when a job is booked. Add rules for property age, brand and photos. Example: “Boiler brand = Vaillant + no heat → include ignition electrodes and seals.”

- As data grows, trial AI suggestions that score the likelihood of each part. Keep the human in the loop to approve.

3) Keep a live van stock mini-list

- Stabilise 20 to 40 must-carry items per van. Use barcodes and a quick weekly count so your list is trustworthy. See our barcode setup guide linked above.

- Aim for light and fast. Overloading the van slows you down and hurts fuel use.

4) Run a daily “kit-up” check

- Each afternoon, generate tomorrow’s picklists and compare to the van list.

- Anything missing is ordered for Click and Collect. Screwfix is often fastest; many merchants offer similar cut-offs. Check official guidance for timing in your area.

5) Pre-stage by job and load smart

- Bag or box parts per job with the job number on it. Keep them near the side door in visit order.

- Add a disposable tray for small fixings so nothing gets lost.

6) Close the loop with usage capture

- After each job, tick the parts actually used. This trains your rules and AI.

- Flag “not on van” parts that forced a second visit; these are gold for improving the lists.

KPIs to track

- First-time fix rate (7 to 14 day window). See plain-English definition at Totalmobile.

- Repeat-visit rate and average days to resolution. Aquant’s benchmarking indicates failed first visits add roughly two extra visits and a notable delay to resolution on average (summary).

- Parts availability hits: how often you had everything to finish.

- Cost per job and van weight trend.

Common pitfalls and how to avoid them

- Over-stocking the van: carry staples only; use daily picklists for the rest.

- Dirty data: if your job notes don’t record parts used, your suggestions will be weak. Start capturing now.

- No staging time: block 20 to 30 minutes late afternoon for kit-up. It pays back the next day.

- Ignoring customer comms: accurate ETAs and confirmations reduce wasted trips. See our no-show playbook for WhatsApp reminders and templates: WhatsApp appointment reminders.

- Skills mismatch: even with the right parts, the wrong engineer can still cause a callback. See our rota playbook: Assign the right engineer every time.

Real-world inspiration: racking and layout

A short, practical van tour showing how another UK plumber lays out racking and small-parts storage:

What people are saying on Reddit

Recent trade threads back up the idea of carrying a tight set of staples, then topping up for each job. Highlights:

- “Screws, lots of different screws” and store them so you can actually find the one you need.

- Keep toilet fixings, P-trap parts, tape and compound, plus a small selection of valves and flexis.

- Don’t overload the van; plan materials and use Click and Collect instead.

Read the thread: Handyman Truck/Van stock materials

Put it together: a simple starter kit

- Data: a spreadsheet with job type, fault, parts used.

- Rules: a two-column table mapping job type → parts.

- Van list: 20 to 40 staples with barcodes.

- Daily habit: generate picklists at 4pm, order gaps for Click and Collect.

- Review: every Friday, add anything that caused a second visit to next week’s rules.

For routing and time windows that make your ETAs more accurate, see our playbook on route planning for trades.

Sources and further reading

- What FTFR means in plain English: Totalmobile

- Cross-industry context: Field Technologies Online

- Benchmarks and AI effects: Aquant 2025 benchmark summary

- Click and Collect timings: Screwfix FAQ

FAQ

Does this need a data scientist?

No. Start with common-sense rules from your own history. Add AI when you’ve a few hundred labelled jobs.

We already carry lots of stock. Why change?

Heavy vans cost fuel and still miss oddball parts. Carry staples, then top up per job using daily picklists and Click and Collect.

How fast can Click and Collect be?

When an item is in local store stock, Screwfix quotes readiness in as little as 1 minute. Items sent to store are typically next day. Always wait for the ready text before travelling. See Screwfix FAQ.

What KPI target should we aim for?

If you’re mid 70s, target 80 percent first-time fix within one quarter. Top performers run 85 to 90 percent…

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist