RAMS for UK construction: simple steps, free template and how to brief your team

Jump To...

Foreman reviewing a RAMS clipboard on a UK construction site

Who this is for

- UK builders, electricians, plumbers, HVAC and maintenance firms who get asked for RAMS before starting work.

- Site supervisors and small contractors who want a no‑nonsense template that aligns with HSE and CDM 2015 without the legal waffle.

What RAMS is in plain English

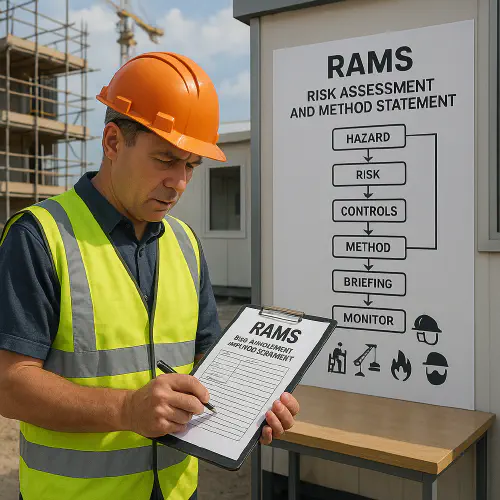

RAMS stands for Risk Assessment and Method Statement. It’s two parts:

- Risk Assessment: list the hazards, who might be harmed, and the controls you’ll use.

- Method Statement: the step‑by‑step safe method to do the job using those controls.

HSE doesn’t make “RAMS” a specific legal document. But you must assess risk, record significant findings if you employ 5 or more people, and for higher‑risk tasks a written safe system of work is expected. RAMS is simply the practical way the construction industry does this.

Helpful HSE pages for context:

- Risk assessment steps and templates: https://www.hse.gov.uk/simple-health-safety/risk/steps-needed-to-manage-risk.htm

- Planning construction work and the Construction Phase Plan under CDM 2015: https://www.hse.gov.uk/construction/safetytopics/planning.htm

- Principal contractor duties (CDM 2015): https://www.hse.gov.uk/construction/cdm/2015/principal-contractors.htm

- Method statements overview in construction: https://www.hse.gov.uk/construction/safetytopics/admin.htm

- Risk assessment template and examples: https://www.hse.gov.uk/simple-health-safety/risk/risk-assessment-template-and-examples.htm

Quick UK rules you must know

- If you employ 5 or more, record significant findings of your risk assessment.

- Under CDM 2015, there must be a Construction Phase Plan on any project. Your RAMS feeds into that plan.

- For higher‑risk activities like demolition, lifting operations, hot works, confined spaces or working at height, a written method statement is standard practice on UK sites.

- Keep RAMS site specific. Generic RAMS alone will be rejected on many principal contractor sites.

Download a simple RAMS template

Paste this into your own document and edit per job. Keep it to 2–4 pages unless the job truly needs more.

PROJECT DETAILS

- Client / Site:

- Address / Work area:

- Job / Task title:

- Date(s):

- Company name:

- Supervisor on site & mobile:

- Other contractors on site:

RISK ASSESSMENT (significant findings)

Task steps | Hazard | Who might be harmed | Controls in place (hierarchy) | Residual risk (L/M/H)

-----------|--------|---------------------|--------------------------------|-----------------------

1. | | | Eliminate/Substitute/Engineer/Administrative/PPE |

2. | | | |

SPECIFIC CONTROLS (tick or describe as needed)

- Working at height: platform class, guardrails, edge protection, fall arrest, rescue plan.

- Lifting ops: appointed person, lift plan, LOLER certificates, exclusion zone, banksman.

- Electrical: isolation/LOTO, 110V tools, RCDs, test before touch.

- Hot works: permit, fire watch, extinguishers, spark containment, gas checks.

- COSHH: SDS on site, ventilation, controls, PPE specified.

- Welfare & first aid: location, first aider, eye wash.

- Traffic/pedestrians: segregation, banksman, speed, deliveries timing.

- Noise/vibration: lower-power method, exposure limits, monitoring.

- Environmental: waste, spill kit, dust suppression, noise hours.

METHOD STATEMENT (safe sequence)

1) Arrival and induction: sign in, site rules, welfare and first aid brief.

2) Set-up: barriers/signage, isolates services, permits in place.

3) Access/egress: safe access fixed; ladders only for short duration and inspected.

4) Carry out task: step by step with named controls from the risk assessment.

5) Test/commission: functional checks, re-energise with LOTO controls.

6) Clear down: remove waste to designated area; reinstate area safe.

7) Handover: client sign-off; update drawings/labels if applicable.

EMERGENCY ARRANGEMENTS

- First aid provision:

- Nearest A&E and route:

- Fire: alarms, assembly point, hot works fire watch duration:

- Rescue plan (for harness/MEWP/Confined space):

PEOPLE & COMPETENCE

- Names of operatives:

- Training/competence: CSCS/etc.; plant cards; IPAF/PASMA; first aider.

PPE

- Mandatory: hard hat, hi-vis, safety boots.

- Task-specific: gloves type, eye/face, hearing, respiratory (RPE type and fit test date).

DOCUMENTS ATTACHED

- Permits (hot works, confined space, electrical isolation), lift plan, drawings, SDS, LOLER certs.

BRIEFING & SIGN-OFF

I confirm I’ve read/understood this RAMS and will follow it. Changes will be agreed with the supervisor.

Name | Signature | Date

-----|-----------|-----

Supervisor approval:

Name/Signature/Date:

Step-by-step: write a RAMS that passes muster

- Define the task and break it into 4–8 steps. Keep each step clear.

- For each step, list realistic hazards and who is at risk (your team, other trades, occupants, public).

- Choose controls using the hierarchy: eliminate, substitute, engineer, admin, PPE. PPE alone is never enough.

- Add specific UK requirements where relevant: permits, LOLER/PUWER, isolation/LOTO, hot works, COSHH.

- Write the method sequence using the controls you chose. Make it easy to follow on site.

- Add emergency and rescue plans. If you use harnesses or enter a void, write how you’ll rescue.

- Attach evidence: certs, SDS, lift plan, training cards. This is what reviewers often look for.

- Keep it site‑specific: name the building/area, access constraints, neighbours, hours, delivery routes.

Brief your team in 5 minutes

Stand at the workface with the RAMS. Cover:

- The job and the boundaries.

- Top 3 hazards and the controls you expect to see.

- Permits and isolations in place.

- Emergency arrangements and who is first aider.

- Questions and sign the briefing table.

Tip: Photos help. Add 2–3 photos of the area and the set-up you expect.

Common mistakes

- Generic RAMS with no site details.

- Long paperwork that no one reads. Keep it lean and practical.

- PPE listed for everything with no higher‑level controls.

- No rescue plan for working at height or MEWPs.

- Missing attachments: lift plan, SDS, LOLER certs, permits.

- No briefing evidence.

Useful links

- HSE risk assessment steps and examples: https://www.hse.gov.uk/simple-health-safety/risk/steps-needed-to-manage-risk.htm

- HSE planning and CDM 2015 overview: https://www.hse.gov.uk/construction/safetytopics/planning.htm

- HSE principal contractor duties: https://www.hse.gov.uk/construction/cdm/2015/principal-contractors.htm

- TrainAR Academy calendar sync guide to avoid BST/GMT headaches on planned works: https://academy.trainar.ai/outlook-servicem8jobbertradify-uk-stop-duplicate-calendar-entries-and-fix-bstgmt-shifts

Related TrainAR Academy articles:

- Construction phase plan made simple: CDM checklist, free template and how to brief the team

- Near miss reporting on construction sites: simple steps, examples and a QR code setup

- Artex asbestos: how to test, NNLW vs non-licensed, safe drilling and removal steps

FAQs

Do I always need a written RAMS

If you’ve 5 or more employees, you must record significant risk assessment findings. Many UK sites require a written RAMS as part of the Construction Phase Plan even for small tasks.

Is there an official HSE RAMS form

No. Use HSE’s risk assessment steps and record a practical method statement where needed. Principal contractors set their own format rules.

Can I use a generic RAMS

Use a good generic starting point, then site‑specific it: building/area, access, adjacent hazards, and task‑specific controls. Most principal contractors will reject a generic copy‑paste.

Who signs RAMS

Your competent supervisor approves it. Then you brief your team and each operative signs the briefing sheet. Keep the signed copy in the site file or app.

How often should I review RAMS

Review if the scope changes, after an incident/near miss, or at least every project. If weather or access changes, update the method and brief again.

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist