Silica dust control plan for small sites: 15-minute workflow, RPE and proof

Jump To...

Workers using wet cutting and M class extraction with supervisor tracking via QR on a UK site

Quick answer

- The UK workplace exposure limit for respirable crystalline silica is 0.1 mg per cubic metre as an 8 hour TWA. You must reduce exposure as low as reasonably practicable with COSHH controls and not rely on masks alone. See HSE.

- On small jobs, a simple stack works: wet cutting or LEV with an M class vacuum and hood, plus FFP3 RPE that has been face-fit tested, plus housekeeping without dry sweeping.

- Prove it: take a quick photo of the setup and log it with a QR code form. That gives you an audit trail for clients and HSE.

What UK law requires in plain English

- COSHH applies. You must assess tasks that make silica dust and control the risk.

- Workplace exposure limit for RCS: 0.1 mg per cubic metre as an 8 hour TWA in GB. There’s no short term exposure limit for RCS in EH40. Start from controls first, then add RPE. Watch for future changes—scientists and campaigners have called for this to drop to 0.05 mg/m³, but no changes are scheduled for 2025–2026.

- Use HSE COSHH Essentials CN task sheets for construction tasks like chasing, scabbling, drilling, cutting and raking out mortar. They specify controls and the assigned protection factor for RPE.

- HSE campaigns like Dust Kills show inspectors are checking extraction, water suppression and whether RPE is face-fit tested. In 2026, expect focus on temporary works, access equipment and rescue planning.

Useful HSE sources you can share with clients and crews:

- HSE silicosis overview and controls: https://www.hse.gov.uk/lung-disease/silicosis.htm

- COSHH Essentials CN series for construction: https://www.hse.gov.uk/pubns/guidance/cnseries.htm

- HSG53 Respiratory protective equipment at work: https://www.hse.gov.uk/pubns/books/hsg53.htm

- HSE chasing concrete and raking mortar guidance: https://www.hse.gov.uk/construction/healthrisks/hazardous-substances/chasing-concrete-and-raking-mortar.htm

- HSE on fit testing basics: https://www.hse.gov.uk/respiratory-protective-equipment/fit-testing-basics.htm

15-minute silica control plan you can run today

- Identify the task and material

- Are you cutting, grinding, chasing or drilling a silica bearing material like concrete, brick, mortar, stone, tiles or sand cement render.

- Pick the primary control before you start tools

- Wet suppression at the blade or bit. Confirm water supply and plan how to manage slurry to avoid slip hazards and contamination.

- Local exhaust ventilation with a hood and a tight hose to a class M vacuum with a filter clean system. Test capture with a quick puff test before work.

- Sometimes both are needed. Example: bench saw outside with water plus extraction on the table saw for off cuts.

- Add RPE matched to the task duration and level

- Most chasing and cutting tasks need at least APF 20. In practice that means an FFP3 disposable mask or a reusable half mask with P3 filters that has passed a face-fit test for the wearer. Keep the seal clean and be clean shaven where it seals.

- Set stop work triggers

- Dust visible beyond 1 metre from the cut. Extraction not capturing. Water not reaching the blade. Worker can’t keep a seal on RPE. Any of these means stop and fix.

- Prove it and brief the team

- Take two photos: control setup and RPE on face. Scan a QR to log job, task, control, RPE and your photos. Send the summary to the supervisor and client site contact if required.

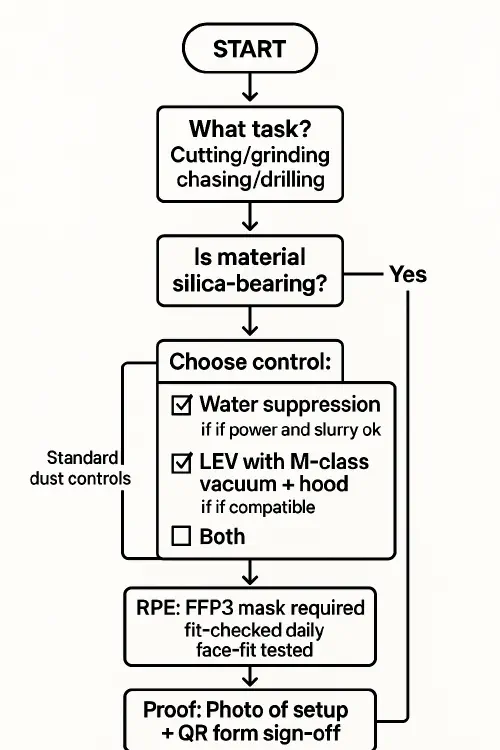

Decision flow you can print and post on the kit box:

Decision flow for picking wet cutting, LEV or both, plus FFP3 and QR proof

Trade task recipes that work

Bricklayers and groundworkers

- Cutting flags and kerbs: Use a bench saw with water suppression outside and RPE FFP3. Control slurry with a collection tray and dispose correctly.

- Raking out mortar: Use a mortar raking tool with an extraction hood and M class vacuum. No dry grinding with a 4 inch grinder without extraction.

Plasterers and dryliners

- Sanding: Use mesh pads and extraction on the sander with an M class vacuum. Short bursts only. FFP3 for sanding over 15 minutes total in a shift.

Carpenters

- Cutting cement board: Only with a saw that has an enclosed hood and M class extraction or cut outside with water suppression. Never dry cut inside.

Electricians

- Chasing walls: Use a twin blade chaser with a close fitting hood and M class extraction. Wet methods can be risky near electrics so usually go LEV plus FFP3.

RPE that actually protects plus face-fit rules

- Pick RPE with at least APF 20 for most silica tasks. FFP3 disposables and half masks with P3 filters give APF 20 when they fit the wearer.

- Face-fit testing is required for tight fitting masks. Do it at selection and again if the model or size changes or the face changes. Daily fit checks are still needed.

- Be clean shaven where the mask seals. If not possible, use a loose fitting powered hood instead.

- Train users to don correctly and to do a user seal check every time.

See HSE HSG53 and fit testing basics:

- HSG53: https://www.hse.gov.uk/pubns/books/hsg53.htm

- Fit testing basics: https://www.hse.gov.uk/respiratory-protective-equipment/fit-testing-basics.htm

Simple proof and records with QR and WhatsApp

You only need a minimal trail that you can produce on request.

- QR control card on the tool case. It opens a simple form to capture job, task, control in place, RPE type, photos and a tick to confirm the brief.

- WhatsApp group for the site. After the QR form is submitted, share the summary so supervisors can act quickly if something is missing.

- File automatically to a cloud folder by site and date. That keeps you ready for HSE or client audits.

Related Academy guides you can use to set this up fast:

- Near miss reporting with QR: https://academy.trainar.ai/near-miss-reporting-on-construction-sites-simple-steps-examples-and-a-qr-code-setup

- Toolbox talks that crews actually follow: https://academy.trainar.ai/toolbox-talks-uk-what-hse-expects-free-5minute-scripts-and-a-printable-signin-sheet

- RAMS made simple for UK construction: https://academy.trainar.ai/rams-for-uk-construction-simple-steps-free-template-and-how-to-brief-your-team

Monitoring that makes sense for small sites

- Real time particle monitors are useful for a quick sense check but not a legal pass or fail. Use them to compare before and after you put controls in.

- Place the monitor near the breathing zone but out of harm. Watch for spikes during cuts. If you see spikes, stop and improve capture or wetting.

- For formal exposure data, use an occupational hygienist. BOHS Breathe Freely has contacts and practical advice.

Useful link: https://breathefreely.org.uk

What are people saying on Reddit

Real conversation sparks two key points: one off exposure is not the same as daily exposure, and the industry can be too casual about silica if controls are not enforced. Worth a read for supervisor coaching.

- Thread: Worried about silica dust exposure. https://www.reddit.com/r/Construction/comments/1kcnx0d/worried_about_silica_dust_exposure/

Useful links and related Academy guides

External

- HSE silicosis and controls: https://www.hse.gov.uk/lung-disease/silicosis.htm

- COSHH Essentials CN series: https://www.hse.gov.uk/pubns/guidance/cnseries.htm

- HSE chasing concrete and raking mortar: https://www.hse.gov.uk/construction/healthrisks/hazardous-substances/chasing-concrete-and-raking-mortar.htm

- HSG53 RPE guide: https://www.hse.gov.uk/pubns/books/hsg53.htm

- HSE fit testing basics: https://www.hse.gov.uk/respiratory-protective-equipment/fit-testing-basics.htm

- CITB Construction dust CIS36: https://www.citb.co.uk/media/e3kgvp1o/cis36.pdf

Internal

- Toolbox talks UK: what HSE expects: https://academy.trainar.ai/toolbox-talks-uk-what-hse-expects-free-5minute-scripts-and-a-printable-signin-sheet

- Near miss reporting with QR: https://academy.trainar.ai/near-miss-reporting-on-construction-sites-simple-steps-examples-and-a-qr-code-setup

- RAMS for UK construction: https://academy.trainar.ai/rams-for-uk-construction-simple-steps-free-template-and-how-to-brief-your-team

FAQ

What is the UK limit for silica dust exposure

The workplace exposure limit for respirable crystalline silica is 0.1 mg per cubic metre as an 8 hour TWA. There’s no short term exposure limit in EH40. You must control dust and reduce exposure as low as reasonably practicable.

Is one weekend around concrete dust likely to cause silicosis

Unlikely by itself. Silicosis is mostly linked to repeated high exposures over time. You should still avoid any unnecessary exposure and use controls on every job.

What mask do I need for cutting concrete

Use RPE with APF 20 such as FFP3 disposable or a reusable half mask with P3 filters, but only if it fits your face and has been face fit tested. RPE is the last line after wet cutting or LEV.

Is wet cutting enough on its own

Often yes outdoors if water hits the blade and slurry is managed, but add RPE if you’re close to the cut or if wind is pushing mist back to the breat…

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist