Underfloor heating not working: step-by-step fixes for wet systems, common faults and when to call it

Jump To...

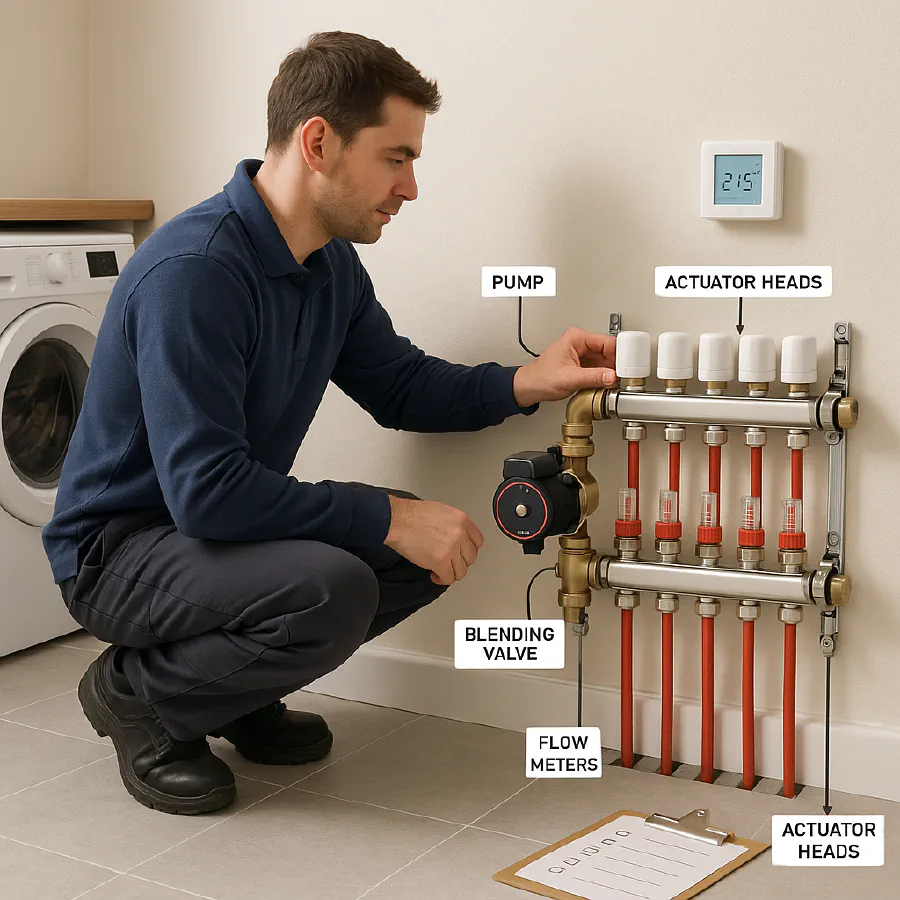

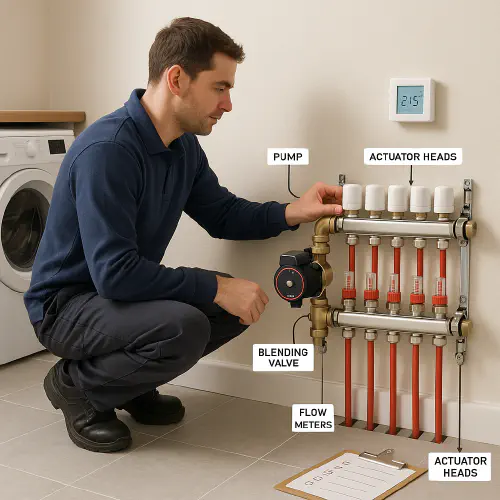

Engineer checking a UFH manifold with pump, mixing valve, flow meters and actuators in a UK utility room

Quick answer

Most “UFH not heating” callouts come down to a few checks:

- Thermostat calling for heat and powered on.

- System pressure around 1.0–1.5 bar cold; top up and bleed if low.

- Manifold pump running, mixing valve around 35–45°C depending on floor finish.

- Delta‑T across loops near 5–7 K; if much higher, increase flow or bleed air.

- Single cold room? Check the actuator head is opening and the valve pin isn’t stuck.

- Air or sludge? Bleed loops at the manifold and clean the strainer.

Symptoms checklist

- Whole house cold vs one zone cold.

- Pump noisy or silent.

- Flow meters at zero vs bouncing.

- Mixing valve too low or too high.

- Boiler short cycling or not firing on UFH demand.

- After summer restart issues.

How UFH circuits should work

Hydronic UFH recirculates low‑temperature water through floor loops. A mixing valve blends boiler or heat pump flow down to the UFH setpoint, the manifold pump circulates through loops, and actuators open zones on thermostat demand. BS EN 1264 limits floor surface temperatures (roughly 29°C living areas, 33°C bathrooms, up to 35°C perimeter strips). It doesn’t mandate one flow temperature for all homes.

Useful background reading: Nu-Heat on common UFH problems, Ambiente: wet UFH troubleshooting, Easyflow guide.

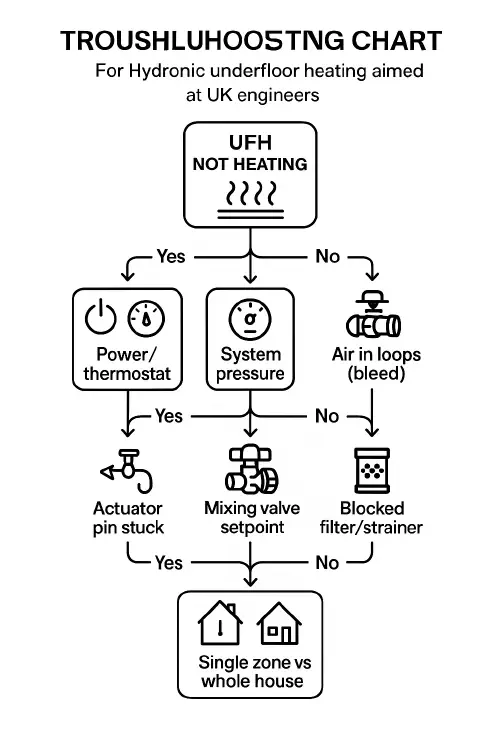

Troubleshooting flowchart for UFH: power, pressure, pump, air, actuators, mixing valve, strainers and single-zone checks

Step-by-step fault-find

1. Thermostat and power

- Check the room stat is powered, set above room temp and actually calling for heat. If it’s a Heatmiser or similar, try a reboot or hold override.

- Electric side: fused spur on, MCB not tripped. For smart stats, confirm receiver calls for heat.

- If you’ve recently changed schedules, some stats limit max floor temp via a probe; make sure the limit suits the floor type.

Reference: Heatmiser FAQ on floor not warm enough and Warmup target temperature tips.

2. Boiler/heat source and pressure

- Check system pressure (typically 1.0–1.5 bar cold). If low, top up via filling loop and bleed air afterwards.

- Boiler should fire when there’s UFH demand; if not, check any wiring centre relays/zone valves linking UFH to the boiler.

- Heat pump? Keep UFH flow temps as low as the building allows for better COP.

Background: CIBSE on low flow temperatures.

3. Manifold: pump, mixer, delta-T

- Pump should run on demand. Start mid to high speed to achieve designed flow, reduce if noisy once balanced.

- Set the thermostatic mixing valve around 35–45°C. Timber/LVT nearer 35–40°C; tile/stone nearer 40–45°C. Respect the surface limits in BS EN 1264 and any floor covering limits (many adhesives/finishes prefer around 27°C at the interface).

- Measure flow and return on the manifold. Aim for 5–7 K delta‑T. If 10 K+ at mild conditions, increase loop flows or clear air.

Useful: RWC/ESBE UFH blending valves ranges, HVP on pressure/flow design.

4. One zone cold: actuator pins and valve sticking

- Is the actuator head opening? Remove the cap and check the valve pin moves freely when you give the head a gentle push. If it’s stiff, try gently freeing it with pliers and silicone spray - don’t force it or you’ll snap the stem.

- Swap actuator heads between ports to see if the fault follows the head or stays on the port (valve pin stuck). If the cold room heats up when you swap, the original actuator head is at fault; if it stays cold, the valve pin is seized.

- Quick field check: put your hand on the pipework just after the manifold port. If it’s hot, the valve is open but actuator isn’t signalling; if it’s cold, the pin is stuck or blocked.

- If replacing pins/heads, isolate and depressurise the manifold first. Keep a spare pin and head on site during the season.

Good visual: Multipipe’s video on actuator pins replacement.

5. Air, blockages and strainers

- Bleed each loop at the manifold return one at a time until a steady flow with no bubbles. Open the bleed screw just a quarter turn - don’t let all the water out. If it’s hard to turn, soak it with penetrating oil first.

- Clean any Y‑strainers/filters feeding the UFH circuit. Sludge can starve the manifold of flow. If you find black magnetite, don’t just clean it - it’ll come back. You need a magnetic filter on the main boiler return, not just the UFH strainer.

- After summer, pumps can stick. Spin the pump shaft with a screwdriver if your model allows - turn it back and forth a few times to break the seal. If it won’t budge, try a gentle tap with a soft mallet, don’t force it.

- Pro tip: listen to the pump. A grinding noise means bearings are dying, not just sludge. If it’s seized solid and you can’t free it, it needs replacing.

Guides: Ambiente on air in pipes, Heat Mat troubleshooting.

6. Balancing and flow meters

- Typical loop flows are 1–3 L/min. If no design data, a rough starting point is loop length divided by ~40 for L/min. Adjust to hit room temp with ~5–7 K delta‑T.

- Use the manifold flow meters to set each loop. Prioritise the longest loops, then trim shorter ones so all zones warm evenly.

Reference kit: 0–3 L/min flow meters.

7. Floor finishes and surface limits

- BS EN 1264 caps floor surface temperatures for comfort and safety.

- Many timber/LVT manufacturers and BS 8203‑aligned adhesive guidance prefer a 27°C interface limit. Use a floor probe to enforce this.

More detail: Altro UFH guidance and Warmup on floor finishes.

Safe starting presets for UK homes

- Mixing valve: 35–40°C for timber/LVT/carpet; 40–45°C for tile/stone.

- Delta‑T: aim 5–7 K across loops.

- Loop flows: 1–3 L/min typical; total manifold flow = sum of loops.

- Pump: start mid to high; reduce if noisy once delta‑T and room temps are met.

Background reading: Underfloor Heating Systems Ltd guidelines.

When to call an engineer

- Electrical cable damage suspected, or stats/wiring centre faults.

- Noisy pump bearings or seized pump after summer.

- Mixing valve failure or boiler not being correctly signalled by UFH wiring centre.

- Persistent pressure loss or sludge; may need power flush or magnetic filtration.

- Any buried repair to UFH pipework. Joints under floors should be avoided; if unavoidable, use manufacturer‑approved press fittings with sleeves, not generic compression joints.

What are people saying on Reddit?

Recent UK threads highlight the risk of using compression joints under floors and the preference for press fittings when a UFH loop has to be repaired in situ. See this discussion: Underfloor heating repair advice.

Related articles

- How to use a thermal camera on site: find leaks, damp and hot connections

- How to take a card pre-authorisation on site with Square (and when to use deposits instead)

- Record business calls legally: simple setup on 3CX, RingCentral and Vonage

FAQ

What flow temperature should I set for UFH?

There’s no single number. Start 35–40°C for timber/LVT and 40–45°C for tile/stone, then adjust to achieve room setpoints while respecting floor surface limits per BS EN 1264.

My UFH worked last winter but not after summer. What changed?

Pumps stick, air collects, and valves seize. Free the pump, bleed each loop, and check actuator pins.

One room is cold but others are fine.

Check that zone’s actuator head and valve pin, confirm that loop’s flow meter shows movement, and bleed that loop. Swap the actuator to confirm if the fault follows the head.

Boiler runs but floors stay cool.

Mixer may be set too low, strainer blocked, or pump speed too low. Check delta‑T. If delta‑T is high, increase flow or clear air.

Can I repair a cut UFH pipe under the floor?

Joint‑free is ideal. If a repair is unavoidable, many pros prefer press fittings designed for UFH with protective sleeves. Avoid generic compression joints beneath finished floors.

What surface temperature limits apply?

BS EN 1264 references common limits around 29°C for living areas and 33°C for bathrooms, with edge zones up to 35°C. Many floor finishes prefer about 27°C at the adhesive interface.

Ready to Transform Your Business?

Turn every engineer into your best engineer and solve recruitment bottlenecks

Join the TrainAR Waitlist